Case Introduction

In recent years, concerns over overcapacity in lithium battery materials have become increasingly prominent, while price wars among downstream automotive manufacturers continue to intensify. The introduction of end-to-end intelligent logistics will become the key for lithium battery companies to enhance market competitiveness and break through the status quo.

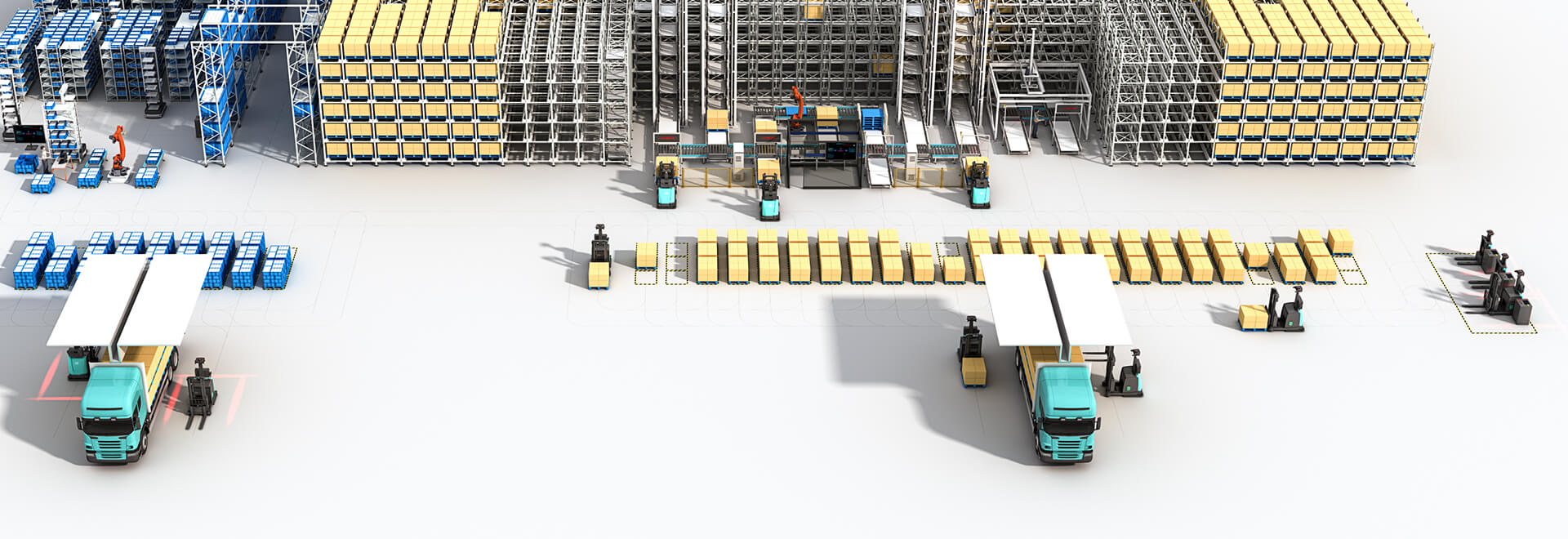

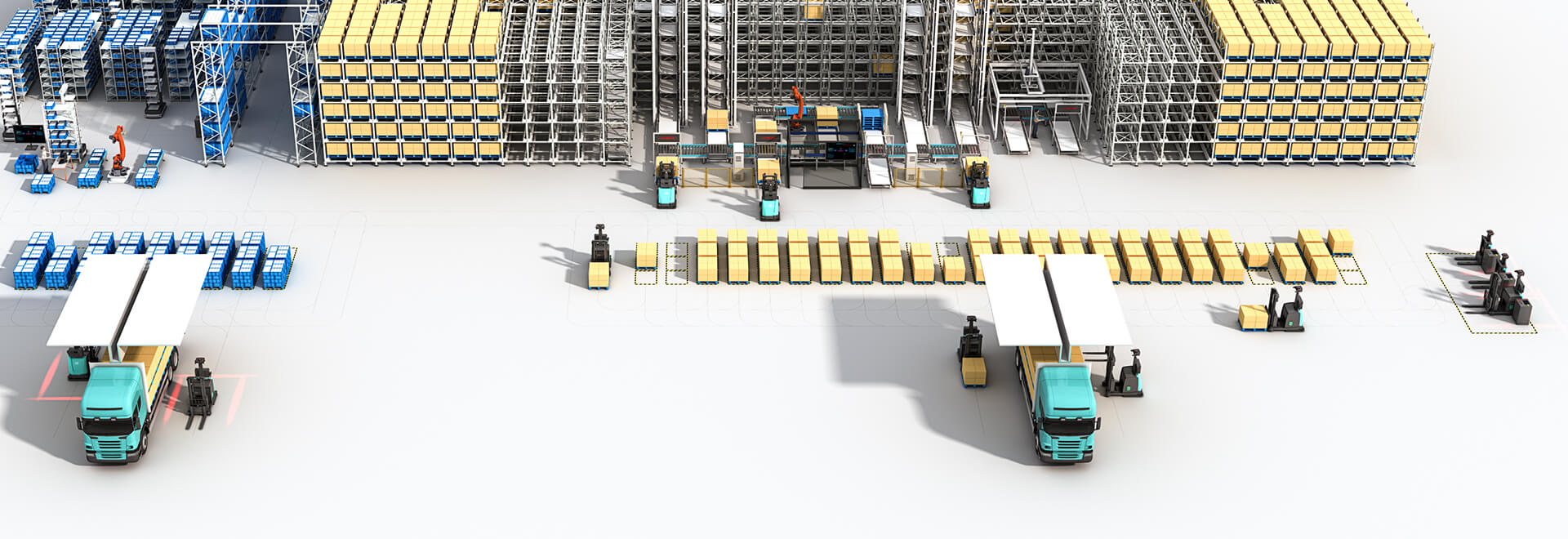

CATL, the world’s largest new energy battery manufacturer, upholds an almost rigorous “extreme manufacturing” philosophy. With the support of Multiway’s intelligent logistics solutions, CATL has established the world's first intelligent and flexible energy storage production line.

Through technological transformation, CATL boosts the efficiency of traditional production lines, accelerates intelligent manufacturing to embrace digital opportunities, and advances green manufacturing to achieve higher energy efficiency and environmental sustainability. As a leading enterprise in the new energy sector, CATL has set a benchmark for “digital manufacturing” and “Industry 4.0.”

1. What does an energy storage production line produce?

Put simply, it produces “large power banks.”

2. How big are they?

Each unit weighs 4 tons, and measures 1.3 meters in length and width, and 2.4 meters in height.

Before introducing Multiway’s autonomous forklift solution, the company relied on manual forklifts to perform mechanical and highly repetitive tasks. Due to the height and weight of the cabinets, manual handling frequently resulted in collisions and tipping incidents. In addition, operating large counterbalance forklifts within narrow workshop spaces created significant safety risks for personnel, vehicles, and goods.

Furthermore, the production process was complex, required high precision, and involved frequent process adjustments, along with extensive coordination with automated equipment. These factors made manual operations difficult, inefficient, and costly.

Multiway provided an autonomous forklift collaborative solution tailored to the customer’s needs. The wide-leg clamping autonomous forklift MW-LS40WC is deployed to handle heavy-load transportation, mitigating tipping risks and saving aisle space.

By adding an additional buffer station, the production line was segmented into zones, reducing the risk of line stoppage at upstream workstations under long process linkages. This ensures that the production capacity of each zone is not affected by the cycle time of preceding or subsequent processes.

Multi-vehicle collaboration and stepwise circulation enable the automatic transfer of energy storage cabinets between processes without human intervention. While reducing labor requirements, a “Horizons” vision system is deployed to ensure production safety, achieving zero errors in personnel detection and vehicle coordination.

Today, CATL is rolling out green, high-end intelligent manufacturing across its global sites. The benchmark dynamic energy storage line solution, combined with other smart manufacturing technologies, is being replicated and scaled internally, leading to a significant competitive advantage. As a result, workforce requirements have been reduced by 70%, operational speed has increased by 300%, and product defect rates have reached a DPPB level.