Storage Upgrade Secret of a Leading Motor Manufacturer: MuVit Autonomous Forklifts Double Operational Efficiency

Video

Video

Case Introduction

In today’s era of accelerated global manufacturing transformation, intelligence and digitalization have shifted from being “optional” to a “must-have” for corporate survival and growth. As market demand becomes increasingly personalized and orders shift toward smaller batches and higher frequency, traditional mass production and logistics models face unprecedented challenges. This is especially true in the motor and electromechanical manufacturing sectors, where diverse product models, complex materials, and frequent warehouse movements place extremely high demands on the speed, accuracy, and flexibility of warehousing and logistics operations.

To address this challenge, a leading Chinese motor manufacturer—listed on the stock exchange and exporting its products to over 30 countries and regions worldwide, partnered with Multiway Robotics to successfully deploy an autonomous forklift-based smart logistics solution at its core manufacturing facility in South China. This deployment has enabled a full transition from manual material handling to end-to-end intelligent scheduling, establishing a replicable and reference-worthy benchmark for smart logistics in the industry.

As business scale continues to expand and order structures evolve, the company’s South China manufacturing base has progressively shifted toward a flexible production model characterized by small batches and high frequency. The existing warehouse operations—primarily reliant on manual forklifts—can no longer keep pace with current production rhythms or meet the demands of refined management. Critical pain points have thus become increasingly evident:

High reliance on manual labor: Rising labor costs and insufficient workforce stability.

Limited operational efficiency: Manual material handling and manual record-keeping operate in parallel, resulting in fragmented workflows and inconsistent operational rhythm.

Inefficient space utilization :The traditional flat-storage model can no longer support the company’s expanding business needs, and warehouse bottlenecks are becoming increasingly evident.

Complex Safety Management: In mixed worker-vehicle environments, safety risks are high and control is challenging.

Solutions

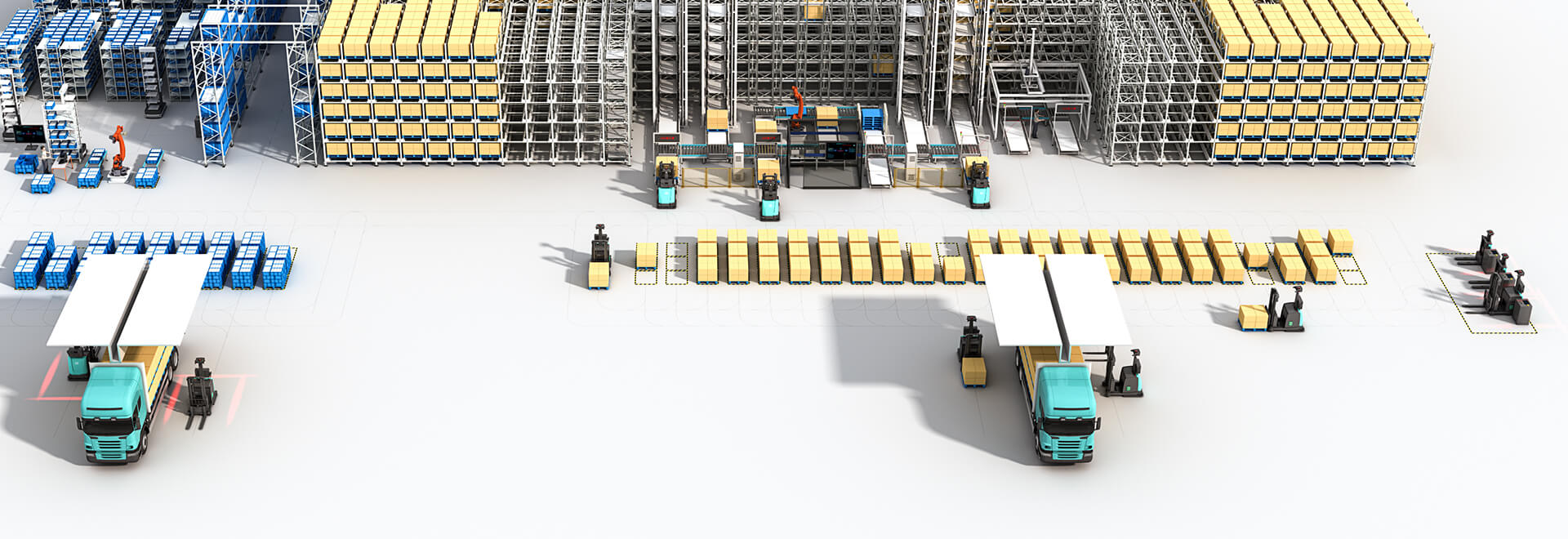

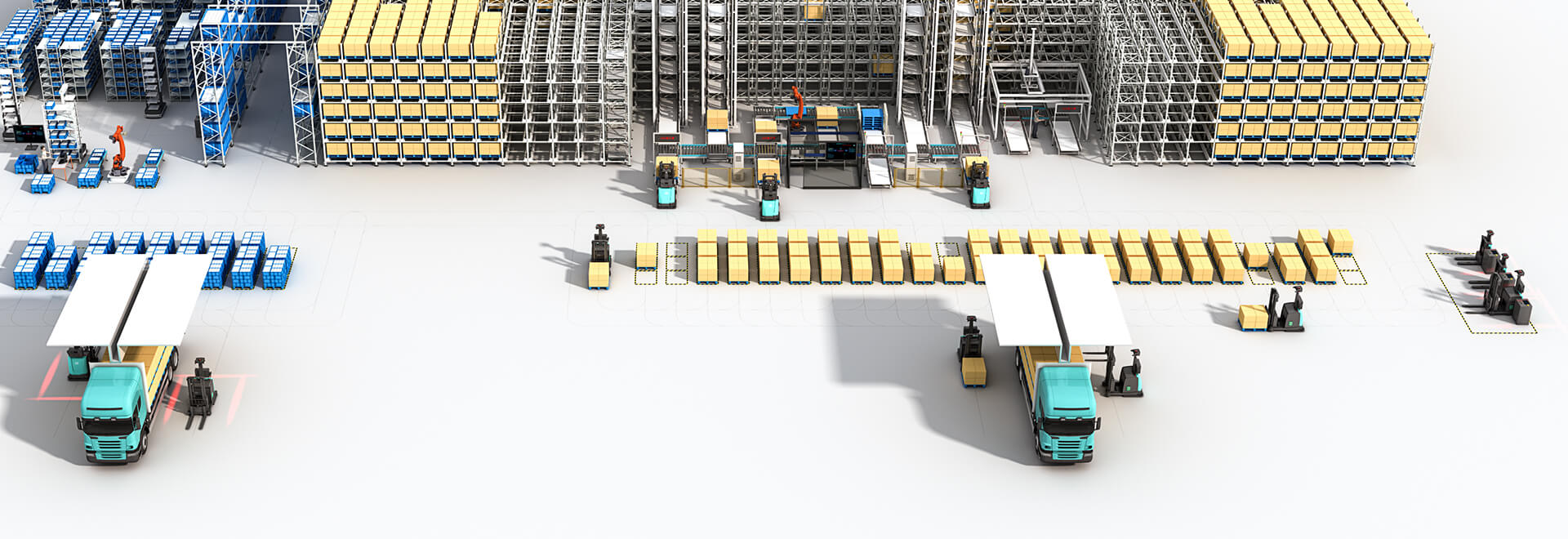

In response to the motor manufacturing sector’s unique challenges—diverse material specifications, frequent inbound and outbound movements, and high system integration requirements—Multiway Robotics delivered a comprehensive smart logistics solution covering both raw material and finished goods warehouses, enabling a full upgrade from operational execution to management-level intelligence.

The project deployed Multiway Robotics’ counterbalanced stacker AGV, the MW-L20, featuring a payload capacity of 2,000kg and a maximum lift height of 5 meters, making it ideal for high-bay racking systems and fully capable of meeting demanding, high-frequency, high-level storage operations.

The WMS (Warehouse Management System) is deeply integrated with the enterprise’s existing SAP system, enabling end-to-end automated data flow—from production work orders and goods receipt, through inventory management, to outbound shipping instructions—effectively eliminating information silos.

The RCS (Robot Control System) acts as the “traffic commander,” providing centralized scheduling and intelligent path planning for multiple autonomous forklifts to ensure efficient coordination and safe operation under concurrent task execution.

Following project implementation, the company’s South China manufacturing base has achieved a systematic enhancement in warehouse operational capabilities:

Upgraded Operational Model: Warehouse tasks have shifted from manual dispatch to centralized system scheduling, with autonomous forklifts reliably supporting concurrent multi-task execution.

Significant Space Optimization: Leveraging the 5-meter lift height and high-density racking solutions, storage capacity has been substantially increased within the existing footprint.

Enhanced Management Capabilities: Real-time visibility into inventory and operational status has improved both inventory accuracy and on-site control.

Improved Safety and Reliability: High-frequency manual handling has been replaced by autonomous forklifts, reducing risks associated with pedestrian-vehicle coexistence and ensuring more standardized, orderly operations.

Multiway Robotics is a global leader in smart logistics solutions, dedicated to empowering intelligent transformation in warehousing, manufacturing, and logistics through cutting-edge robotics technology. Our comprehensive product portfolio includes hardware such as autonomous forklifts, AMRs (Autonomous Mobile Robots), tugger AGVs, and four-way shuttle systems, complemented by a full suite of software—including WMS, RCS, and WCS. Trusted by multiple Fortune 500 companies worldwide, Multiway Robotics enables customers to achieve significant cost reduction, operational efficiency gains, and seamless digital transformation.