Three-Way & Omnidirectional Side-Fork Autonomous Forklifts: Solving High-Density and Complex Material Handling Challenges

Date:2026-01-21

As manufacturing and warehousing shift toward higher density and greater flexibility, traditional material handling faces two key challenges:

1.High-bay, very narrow aisle (VNA) operations:Rising rack heights shrink maneuvering space. Conventional forklifts can’t meet the precision or aisle-width requirements for safe, efficient high-level access—limiting storage density and safety.

2. Long or non-standard loads: Profiles, pipes, and sheets vary widely in length and center of gravity. Front-loading in tight or congested areas reduces efficiency and raises collision risks.

The tighter the aisles, the higher the racks, the heavier or longer the loads—and the more complex the layout—the greater the need for purpose-built equipment, not generic handlers.

Two Flagship Solutions, Addressing Two Core Challenges

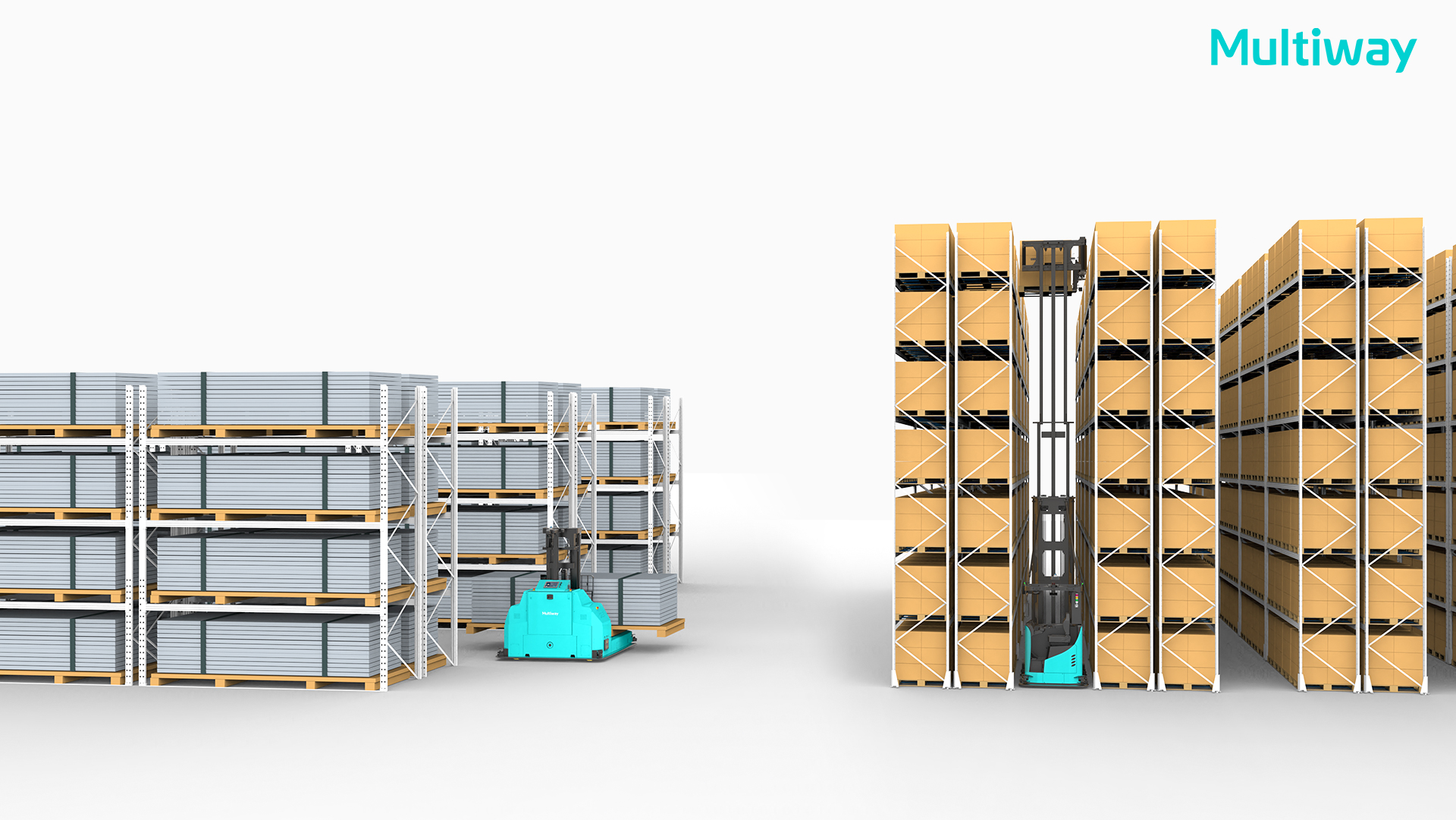

Targeting complex warehousing and manufacturing logistics, Multiway Robotics launches two product lines: the K-series three-way autonomous forklifts and the O-series omnidirectional side-fork autonomous forklifts—tackling the limitations of conventional forklifts from two critical dimensions:space density and handling flexibility.

To truly excel in complex warehousing, an autonomous forklift must solve two core challenges:

store more within limited space, and move loads more stably in constrained environments.。

K-Series Three-Way Autonomous Forklifts

Designed for Very Narrow Aisle (VNA) High-Bay Storage

In automated warehouses and high-density storage systems, the real bottleneck isn’t forklift speed—it’s aisle width and stability during high-level operations.

The three-way autonomous forklift decouples travel, steering, and load handling, enabling precise high-bay pallet placement and retrieval within a fixed aisle—without requiring the entire vehicle to turn. This fundamentally eliminates dependence on wide aisles.

Key Capabilities:

Precise pallet handling up to 16.5 m high in aisles as narrow as 1.75 m

Standardized end-of-arm vision system for millimeter-level positioning accuracy

Fully autonomous operation, eliminating safety risks associated with manual high-level tasks

Typical Applications:

Very Narrow Aisle (VNA) automated warehouses

High-bay, high-density storage systems

Warehousing environments where maximizing space utilization is critical

In high-density storage systems, the three-way autonomous forklift fundamentally determines how densely and how high a warehouse can operate.

O-Series Omnidirectional Side-Fork Autonomous Forklifts

Built for Heavy-Duty and Long-Load Handling

In manufacturing line-side warehouses and long-load storage environments, the key bottleneck is often not load capacity—but limited maneuverability, which leads to frequent repositioning and wasted space.

The O-series omnidirectional side-fork autonomous forklift combines 360° omnidirectional mobility with a side-loading mechanism, enabling efficient handling of heavy and long loads—even in tight spaces—while drastically reducing turnaround maneuvers and non-productive travel.

Key Capabilities:

Multi-directional movement (forward, backward, lateral, diagonal) for superior spatial adaptability

Side-fork design optimized for long materials, oversized pallets, and irregularly shaped loads

Stable and reliable operation for payloads from 2,000 kg to 8,000 kg

Multi-layer safety sensing and obstacle avoidance to minimize cargo damage and collision risks

Typical Applications:

Line-side warehouse and production line logistics integration

Storage of long materials, sheets, and profiles

Handling of heavy pallets and oversized cargo

In complex line-side and heavy-load environments, the omnidirectional side-fork autonomous forklift doesn’t just address whether a load can be moved—it ensures continuous, efficient handling within space-constrained areas.

Different Complex Scenarios Demand Different Autonomous Forklift Solutions

The three-way autonomous forklift pushes the limits of space utilization—solving high-bay storage and ultra-high-density challenges. ;

The omnidirectional side-fork autonomous forklift tackles complex handling tasks—overcoming constraints in maneuverability and heavy-load operations.。

Multiway Robotics remains committed to a scenario-driven approach, leveraging its portfolio of autonomous forklifts and integrated system capabilities to help enterprises build safer, more efficient, and more flexible intelligent logistics systems—within even the most space-constrained environments.

News