Space Utilization Rate Soared by More Than 30% with Multiway High Level AGV Solution

Date:2025-05-15

In the field of intelligent logistics, are you worried about the low efficiency of high-level storage and retrieval, high safety risks, and large space waste of high-level shelves? Multiway Robotics high-level storage & retrieval AGV forklift solution breaks the traditional shackles with innovative technology, helping to increase the utilization rate of storage space by more than 30%, achieving a win-win situation of safety and efficiency.

Three Major Pain Points, Solved with One Solution

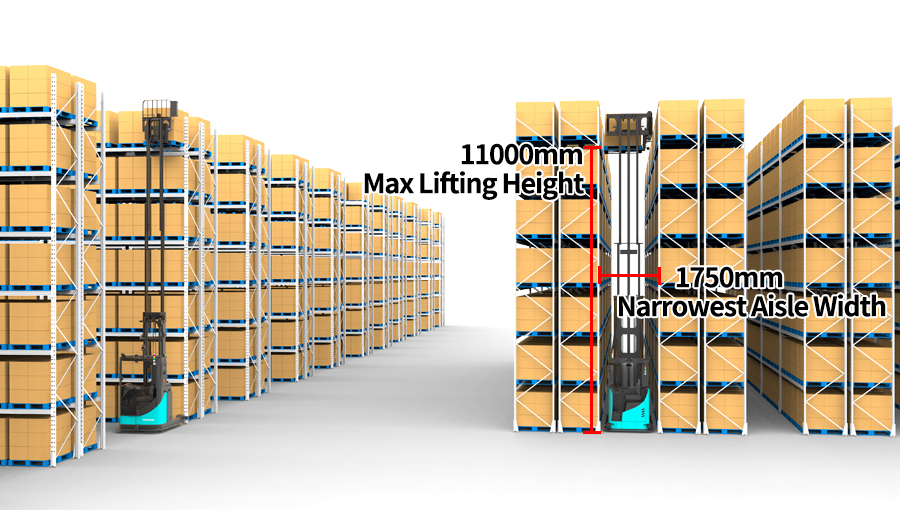

Traditional forklifts need to reserve a passage of more than 3 meters, which takes up 30% of the warehouse area. Multiway AGV forklifts only need a 1.75-meter passage, and the shelf height is up to 11 meters, which greatly increases the space utilization rate.

The accident rate of manual forklifts over 8 meters is as high as 0.23%! Multiway AGV forklifts are equipped with high-precision visual perception and intelligent obstacle avoidance systems, and the operation is fully automated, with zero risk.

10% of orders are cancelled due to timeout in finding goods? RCS intelligent dispatching system seamlessly connects to WMS warehouse management system, responds to order changes in seconds, and reduces the error rate by 100%!

Multiway Robotics has been deeply involved in high-level storage and retrieval scenarios. Through innovative technologies, it has comprehensively improved the performance of AGV forklifts and enhanced their perception, positioning and control capabilities. Its RCS dispatching system seamlessly connects to the customer's WMS warehouse management system, achieving a comprehensive leap in the intelligence, safety and efficiency of warehouse management. At present, Multiway Robotics' high-level storage and retrieval intelligent logistics solutions have been successfully implemented and maturely applied in many industry projects, continuously creating value for customers.

Customer Pain Point:Low efficiency of 10,000 square meters of warehouse, plus rising labor costs

With the continuous development of intelligent logistics, the safety and efficiency improvement of warehouse management has become an inevitable trend in the industry. With its innovative technology and excellent performance, the high-level storage and retrieval AGV forklift solution of Multiway Robotics has successfully overcome many pain points in traditional high-level storage and retrieval operations, bringing significant benefits to many companies. In the future, Multiway will continue to deepen its roots in the field of intelligent logistics, continuously optimize technology and products, expand application scenarios, help more companies break through the "bottleneck" of warehouse management, achieve the efficient, safe and intelligent upgrade of logistics warehousing, and create greater value for customers.

News