Multiwy Robotics cooperates with a super large chemical enterprise to enable intelligent warehouse upgrade with robot product technology

Video

Video

Case Introduction

In order to reduce enterprise costs and improve logistics efficiency, traditional manufacturing industries have gradually shifted from traditional operation modes to intelligent warehouse modes.

Leading Intelligent IntralogisticsSolution Provider, Multiway Robotics, uses highly flexible robotics technology and products to help enterprises achieve efficient operations throughout the entire process from logistics handling to three-dimensional warehouse storage, and realize the intelligent and modernization of on-site logistics systems.

Recently, the intelligent logistics solution of Multiway Robotic's unmanned forklift was launched in a large chemical enterprise's coking coal production base. Multiway Robotics and its customers jointly built an intelligent warehouse to further enhance the production material supply guarantee capability and improve the intelligent operation level of warehousing.

Software and hardware integration delivery

Unlocking a new model of intelligent warehousing

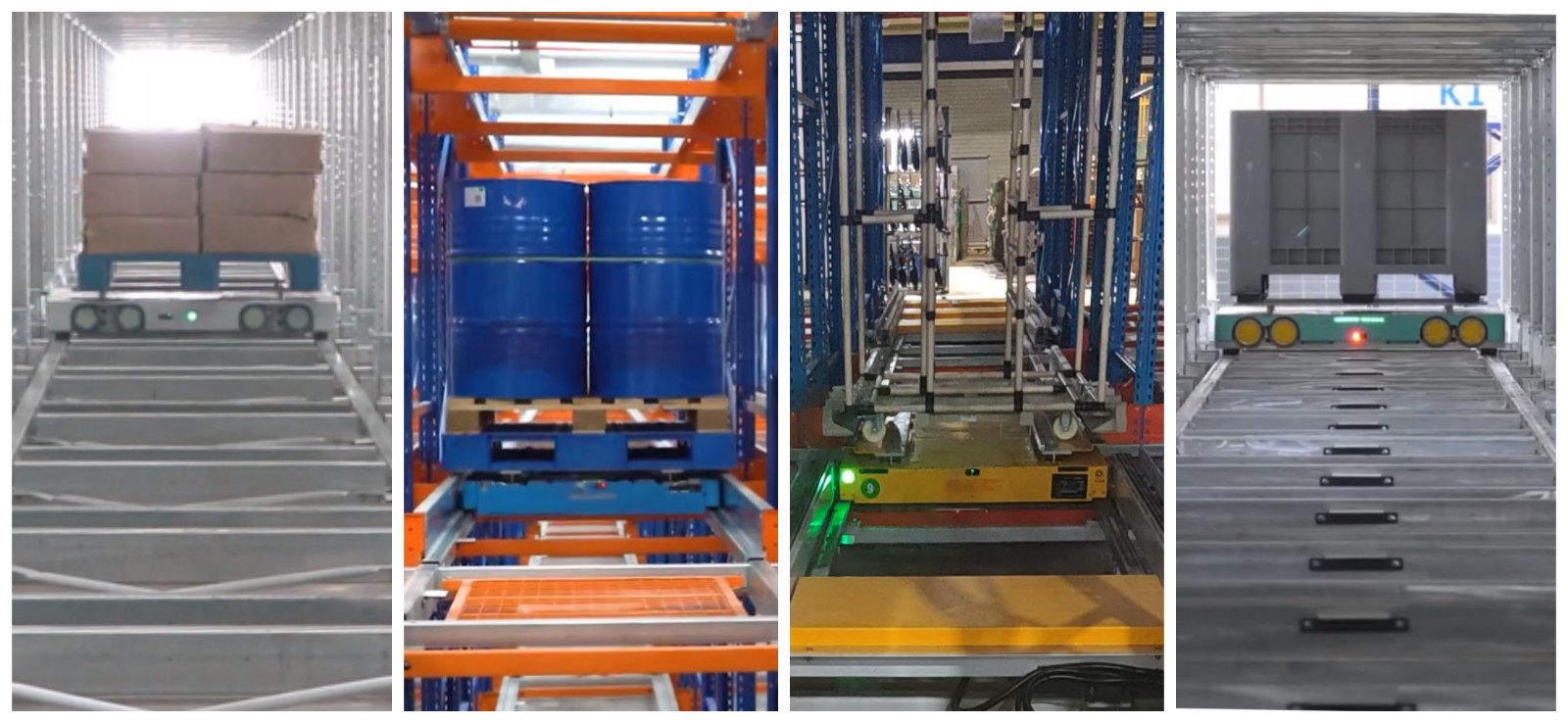

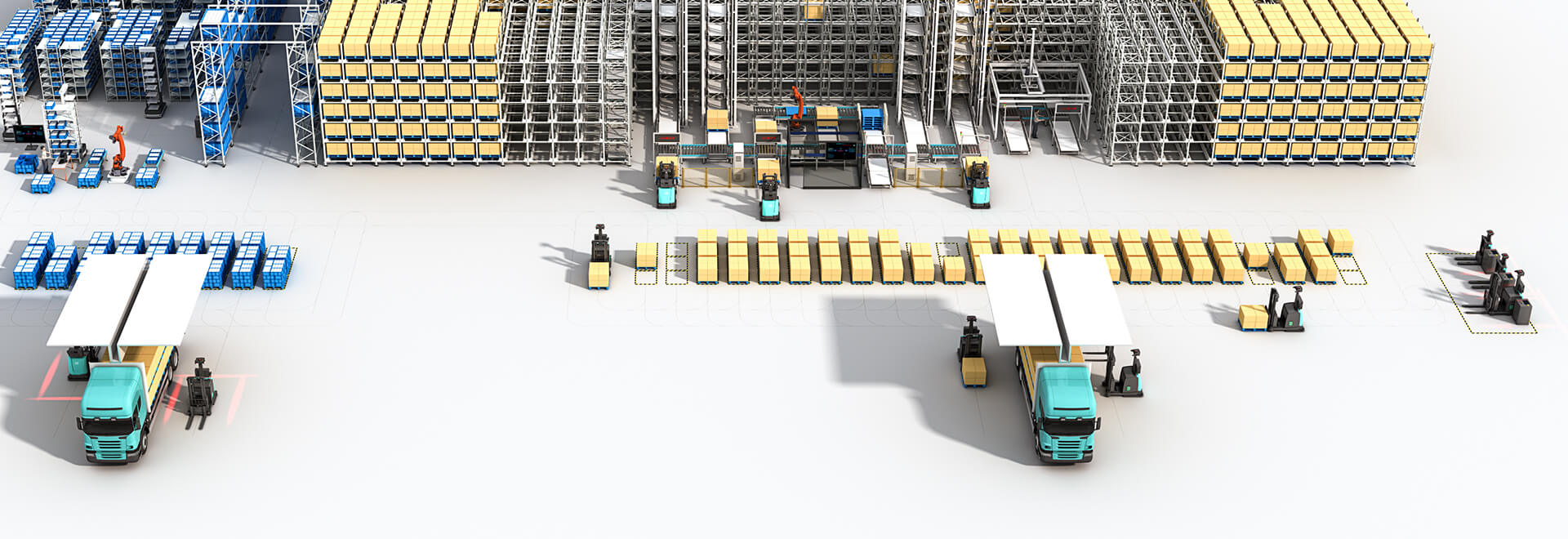

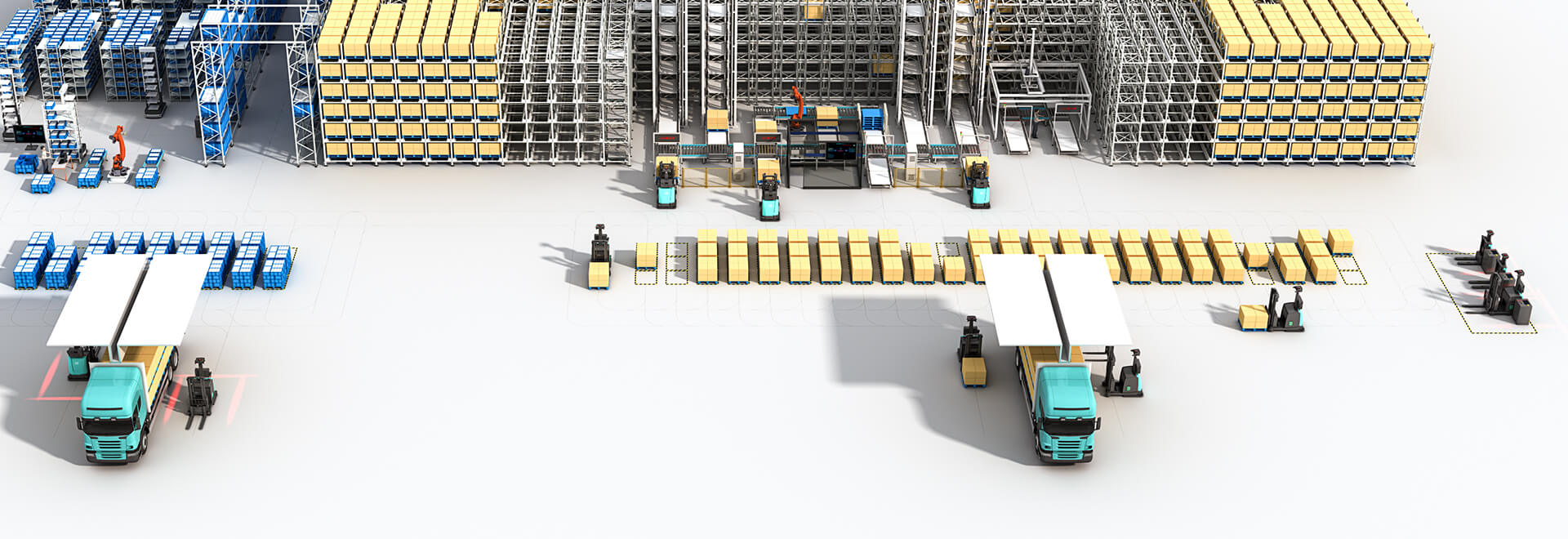

In this China's largest coke production base, the introduction of Multiway Robotics's full-stack intelligent logistics solution with "unmanned forklift + four-way shuttle car" as the hardware carrier, using advanced robotic equipment and solutions, through the integration of WMS, TMS IoT technology and automation equipment, realizes intelligent and unmanned operation of the warehouse, achieving automatic verification of material access and outbound, management of incoming vehicles and goods information, three-dimensional storage, sorting, distribution route optimization and delivery acceptance functions.

In a 4,000-square-meter three-dimensional warehouse, six-story dense storage three-dimensional warehouse + four-story high-level beam rack, unmanned forklift external handling, intelligent four-directional internal storage access, saving 14,200 square meters of warehouse space and storing more than 860,000 items.

The integrated hardware and software system covers logistics operations from receiving, storage, distribution, return, and replenishment of materials, comprehensively revolutionizing the delivery time and inventory turnover collaboration efficiency.

Multi-system intelligent integration

Multi-vehicle cluster scheduling

Improve operational efficiency

Increase warehouse capacity

Multiway Robotics can provide integrated solutions for handling and storage, and has projects in many industries, including the consumer goods industry, automotive industry, electronics and electrical industry, machinery manufacturing industry, chemical industry, and many other industries. It is widely recognized by many customers.