Case Introduction

The chemical industry has a complex process, with 80% of its major raw materials and products classified as hazardous chemicals. It faces challenges such as harsh working environments, significant safety risks in handling, complex management, low warehouse space utilization, and difficulties in hiring and high labor costs. Upgrading from traditional production methods towards digitalization, automation, and intelligence has become an inevitable choice for the survival and long-term development of chemical enterprises.

Project Background

This case focuses on a chemical coatings manufacturing company that plans to introduce material handling robots to achieve automation in the transportation of materials from ground-level warehouses, buffer zones, and production lines to the open stage.

Previously, the company relied on manual labor for these operations. However, due to the harsh working environment in the chemical coatings production workshop, characterized by high noise and strong electrical interference, employees' physical health was at risk. Additionally, repetitive material handling tasks led to fatigue among workers. Not only did the company experience a high turnover rate among employees, but the reliance on manual labor with its high costs and variability also negatively impacted production efficiency. This created significant challenges in operational management for the company, making it imperative to undergo a comprehensive upgrade to intelligent logistics.

Solution

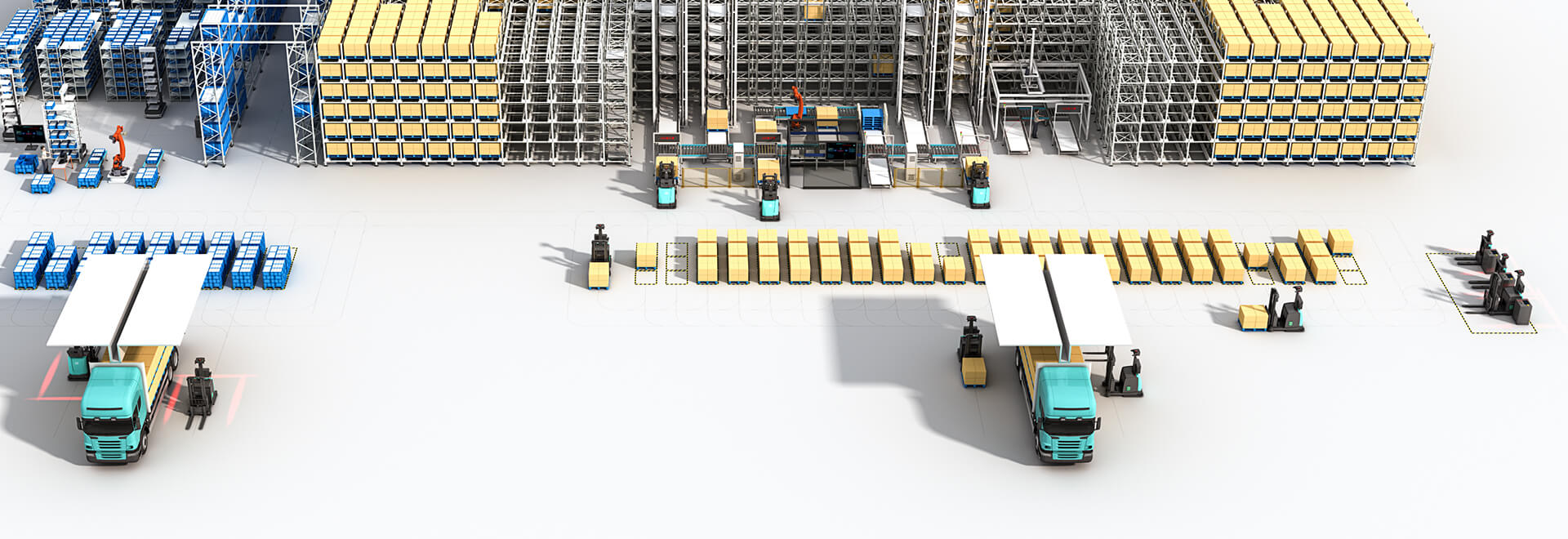

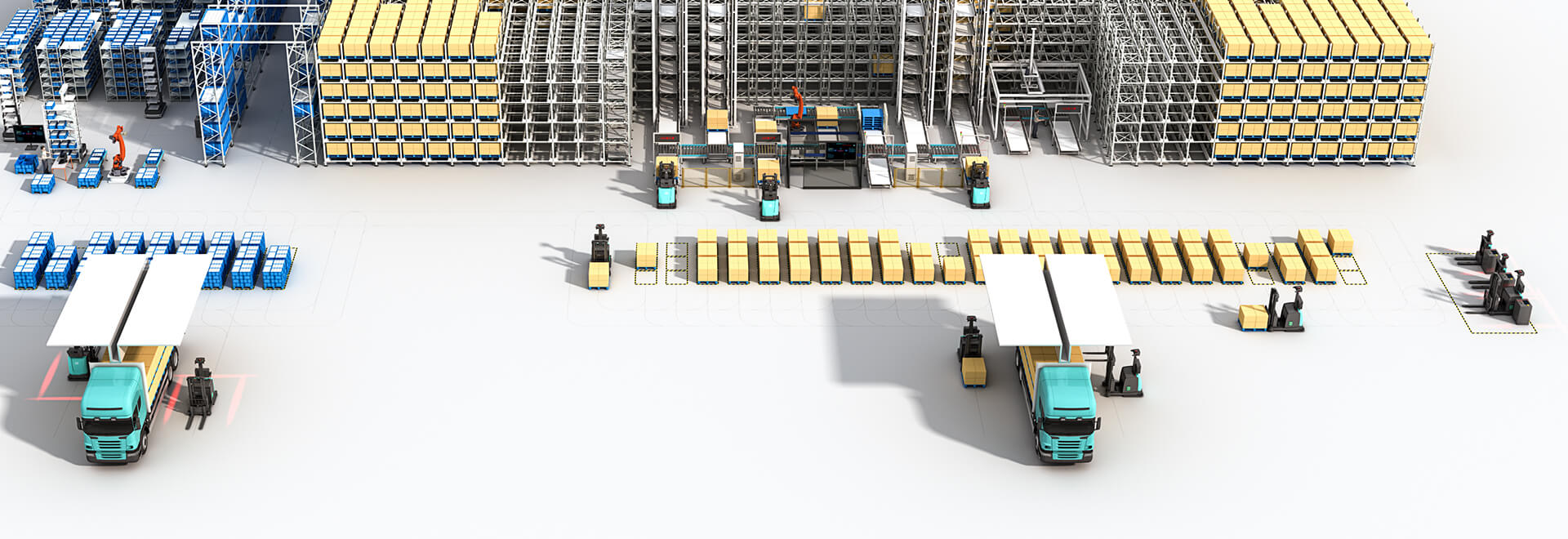

Multiway Robotics provided an integrated hardware and software logistics solution based on the customer's requirements, using the Reach Truck MW-R16 as the hardware product. This solution included a series of automation upgrades, such as conveyor line transportation, pallet dismantling, material handling, and stacking in ground-level warehouses.

Multiple reach trucks were introduced on-site, and they operated without the need for manual supervision, significantly improving production efficiency. With our self-developed RCS scheduling system, these vehicles automatically planned the optimal routes and intelligent traffic management, ensuring timely loading and unloading of production lines and timely inbound and outbound transportation.

Additionally, the WMS (Warehouse Management System) supported the configuration of inbound and outbound strategies and material data management. When there was a switch in production materials on the production line, material code updates could be rapidly completed. The unmanned forklifts could handle loading and unloading, as well as material entry and exit from the warehouse for different types of materials, making operations very convenient. This greatly assisted companies that produce multiple batches of small quantities, enabling flexible and efficient production.

Project Value

After implementing Multiway Robotics' comprehensive intelligent logistics solution, the enterprise has significantly reduced labor intensity for workers while increasing production capacity and efficiency. The factory, which previously operated in three shifts with 8-hour rotations, now uses unmanned forklifts to replace manual labor entirely, enabling round-the-clock unmanned operations.

The initial investment has brought benefits beyond just reducing labor costs. It has also led to the automation upgrade of the factory, satisfying the distribution and automated inbound/outbound requirements for different materials. Additionally, it optimizes warehouse space utilization by stacking goods based on existing storage space, maximizing efficiency. This implementation also digitizes information about goods and automates material handling.

Most importantly, the introduction of Multiway's intelligent logistics solution has made operations more flexible, production more adaptable, and the environment safer, further promoting cost reduction and efficiency improvement for the enterprise, enhancing its competitiveness in the market.

In addition to the case mentioned in the chemical industry, Multiway Robotics' products and solutions are widely used in various industries such as automotive, food, pharmaceuticals, new energy, and 3PL (third-party logistics), covering over 20 different scenarios. By consistently delivering excellent solutions for complex situations and winning benchmark customers across industries, Multiway Robotics continues to empower digital transformation in various sectors.