Case Study | Accelerating Digital Transformation in Automotive Parts Manufacturing with Autonomous Forklifts

Video

Video

Case Introduction

The global automotive market is becoming increasingly competitive, placing higher demands on production quality, efficiency, and operational control. For automotive parts manufacturers, reliable and high-quality component supply is essential to ensure vehicle safety and performance. As a result, the need for intelligent and digital transformation across manufacturing and intralogistics operations has become increasingly urgent.

In this case, we share how Multiway Robotics implemented an intelligent intralogistics solution using autonomous forklifts for a well-known automotive parts manufacturer in South China, supporting its transition toward automated and data-driven material handling.

The customer is an automotive parts manufacturer specializing in plastic automotive components, molds, and plastic granules. With growing production demands and increasing product variety, the company sought to improve logistics efficiency and reduce its reliance on manual material handling within workshops and production lines.

With extensive experience across the automotive supply chain, Multiway Robotics has delivered multiple intelligent logistics projects for both upstream and downstream automotive manufacturers, enabling automated material flow between workshops, production lines, and storage areas.

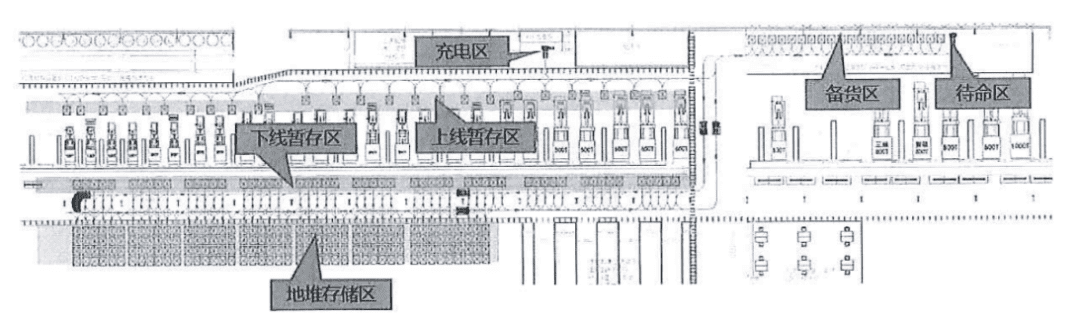

▲总体规划布局

In the raw material staging areas, line-side buffers, and floor storage zones, material handling was previously performed manually. Due to a wide variety of materials and high handling frequency, this approach resulted in:

High labor intensity and operational costs

Limited visibility and traceability of material information

Increased risk of handling errors and damage

Constraints on lean production and process optimization

In a highly competitive automotive industry, traditional logistics models can become a bottleneck for efficiency improvement. The customer therefore required a more efficient, orderly, and intelligent intralogistics system to better control production processes, improve material flow, and support stable production rhythms.

To address these challenges, Multiway Robotics deployed an integrated intralogistics solution covering raw material handling and finished goods storage.

The solution includes two MW-SL14 autonomous pallet stackers, which handle automated material transport between production lines and workshop areas.

Rated load capacity: 1.4 tons

Lifting height: up to 2.5 meters

Compatibility: Supports multiple pallet types, including standard and nine-foot pallets

Performance: Designed for high-precision and high-frequency material handling tasks

The forklifts are integrated with Multiway Robotics’ self-developed software systems, including:

RCS (Robot Control System) for intelligent scheduling

WMS (Warehouse Management System) for inventory and material data management

WCS (Warehouse Control System) for equipment coordination

This hardware-software integrated delivery significantly shortened deployment time while enabling flexible adaptation to multiple logistics scenarios across the facility.

Following the implementation of Multiway Robotics’ intelligent intralogistics solution, the customer achieved measurable operational improvements:

Improved material handling efficiency and production line continuity

Digitalized management of material information, reducing misplacement and delivery errors

Lower risk of material damage during transport

Enhanced production quality and more stable line-side supply

In addition, automation reduced employees’ involvement in repetitive and labor-intensive handling tasks, allowing them to focus on higher-value operational and supervisory activities.

With years of experience serving the automotive industry supply chain, Multiway Robotics has developed scalable, full-stack intelligent logistics solutions. These solutions support a wide range of scenarios—from production lines to warehouses, indoor to outdoor operations, and material transport to storage and retrieval.

To date, Multiway Robotics’ autonomous forklifts and systems have been operating reliably at customer sites across multiple industries, including automotive, food & beverage, new energy, pharmaceuticals, and chemicals, with 1,000+ successfully deployed projects worldwide.