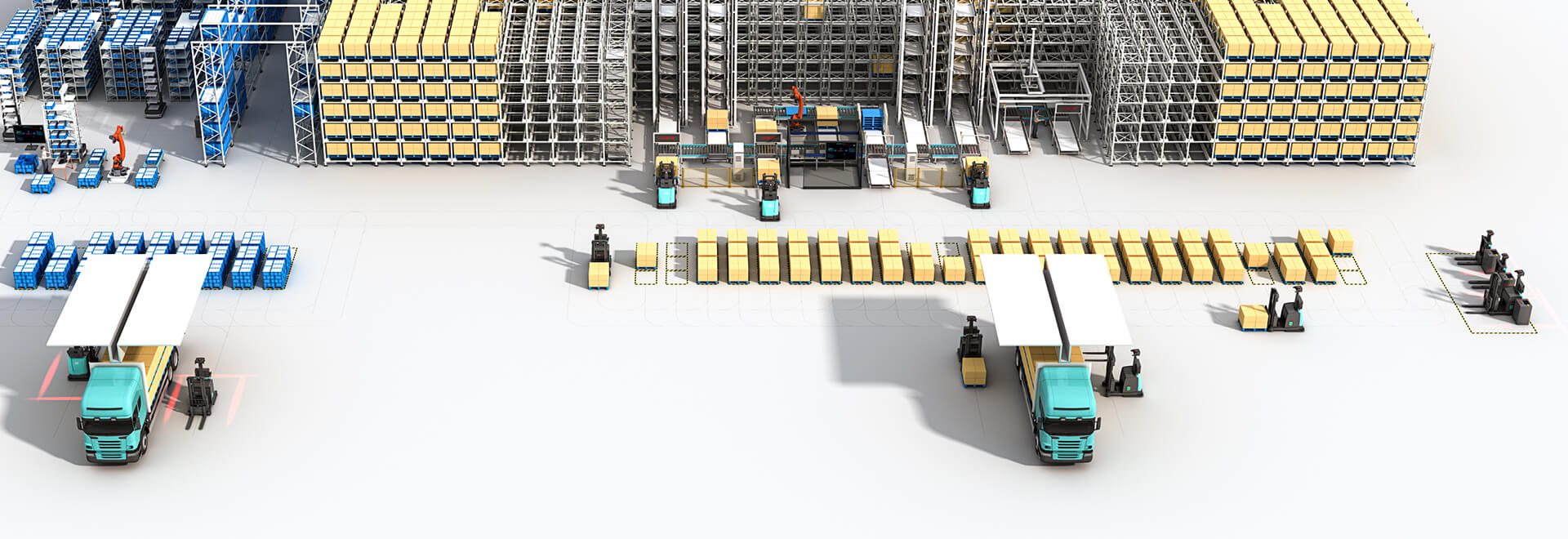

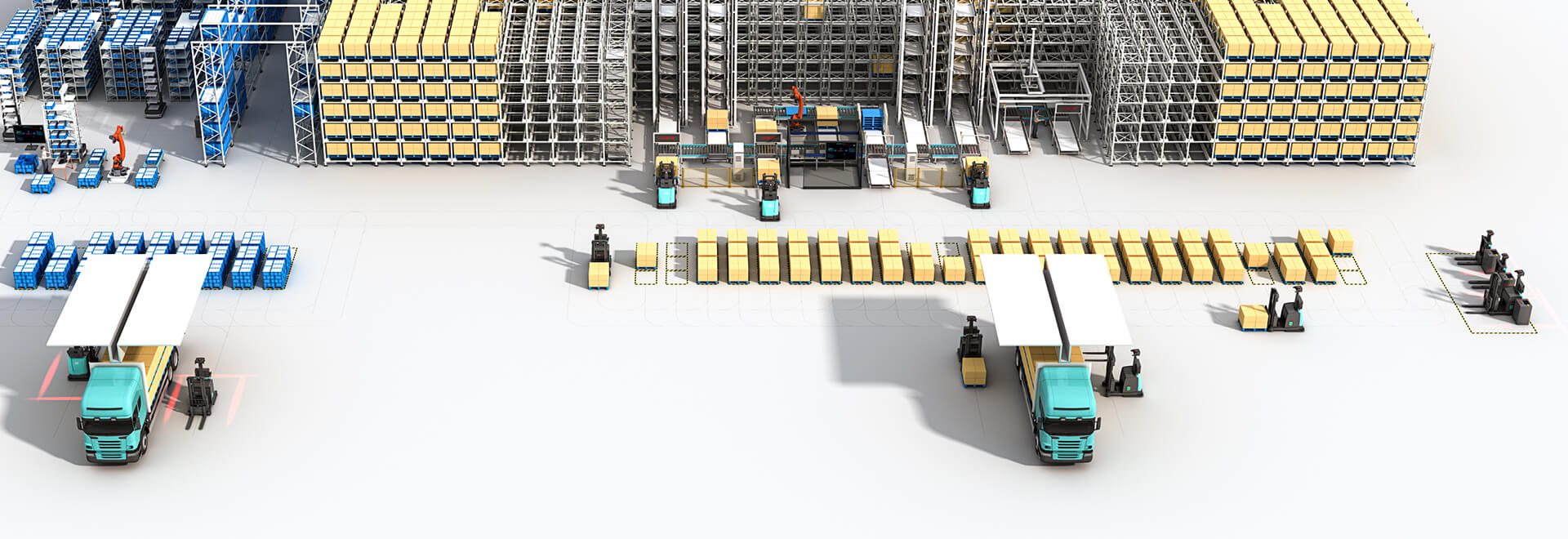

A New Benchmark for Cost Reduction and Efficiency Improvement: Multiway Robotics × Leading Automotive & Motorcycle Manufacturer — Autonomous Forklifts Enable Fully Unmanned End-to-End Operations

Video

Video

Case Introduction

Facing intense market competition and continuously rising operating costs, a leading domestic automotive and motorcycle parts manufacturer partnered with Multiway Robotics to deploy an autonomous forklift solution. Together, they built a flexible unmanned logistics system that integrates intelligent handling, system scheduling, and digital management, achieving fully automated material transport from production lines to warehouses.

The project enables 7×24-hour end-to-end automated operations, increases operational efficiency by over 40%, and significantly reduces labor costs, helping the enterprise establish a highly resilient and scalable intelligent manufacturing system.

Project Background

Multiway Robotics

The customer is a leading manufacturer in China’s automotive and motorcycle parts sector, with annual output reaching tens of millions of units and products exported worldwide. As production capacity expands and multi-product manufacturing runs in parallel, logistics operations relying on manual forklifts can no longer support high-throughput production. The main pain points include:

Low handling efficiency: Manual handling cannot keep up with increasing production line takt times and material turnover frequency.

Information lag: Manual records lead to inaccurate inventory data, affecting production rhythm and planning.

Discontinuous operations: Manual work cannot support 7×24-hour continuous production.

Insufficient safety and flexibility: Mixed traffic of people and vehicles poses safety risks, and system responses lack flexibility.

The Solution

Multiway Robotics

The project covers two major operational workflows: from the production line packaging area to the buffer area, elevator, empty pallet temporary storage and coding transfer area, automated line, and finally the packing area. Based on the customer’s on-site production environment and takt requirements, Multiway Robotics provides an integrated hardware-and-software intelligent logistics solution, enabling seamless connection between the warehouse and production lines with unmanned intelligent scheduling.

Stacker Autonomous Forklift MW-L20: Handles pallet-level material transport tasks from the end of the production line to elevators and buffer storage areas, precisely interfacing with elevators to achieve high-load, high-precision transfer.

Wefront X20: Responsible for material turnover and transfer between workstations within the automated production line, flexibly adapting to multi-station task scenarios.

Warehouse Management System (WMS): Enables refined location management and visual tracking of materials, with intelligent in/outbound strategies to prevent empty slots or misplacement.

Scheduling System (RCS): Intelligently plans travel paths and coordinates multiple vehicles to ensure efficient scheduling in complex aisles.

Equipment Control System (WCS): Integrates elevators, automatic doors, and other equipment, connecting the entire automated workflow.

Project Results

Multiway Robotics

100% Unmanned Coverage

Fully automated material transport from the packaging workshop to warehouse storage.

Operational efficiency increased by 40%+

Reduced labor waiting and return costs.

Data transparency and visibility

Material flow can be monitored in real time.

24-hour continuous stable operation

Unmanned operations support round-the-clock production.

High system flexibility and scalability

The system supports multi-vehicle scheduling, area expansion, and MES integration, providing room for future enterprise development.

Multiway Robotics is a global leading provider of intelligent logistics solutions, dedicated to empowering warehouses, manufacturing, and logistics scenarios through robotic technology. Its product portfolio includes hardware such as autonomous forklifts, AMRs, unmanned tow vehicles, and four-way shuttles, as well as software systems like Multiway Cloud, WMS, RCS, and WCS. Multiway Robotics has served numerous Fortune 500 companies, helping clients achieve cost reduction, efficiency improvement, and digital transformation.