Case Introduction

I always thought regular trucks were huge

— until I saw this giant dump truck

……

The overwhelming presence of this colossal vehicle hits you head-on.

It's hard not to wonder—

Where exactly are these "fighter jets" of the truck world manufactured?

Today, let's follow our guide into the factory

and experience the intelligent manufacturing power

behind these industrial giants.

The client is a well-established heavy machinery group based in Taiyuan, operating several large-scale manufacturing plants. Its products are exported to over 60 countries and regions, making it a globally competitive enterprise in the field of modern intelligent equipment manufacturing.

For the upgrade of in-plant intelligent logistics, the client turned to Multiway Robotics, hoping to leverage its intelligent and flexible AGV forklift solutions to enable safer and more efficient automated material handling within the factory.

👀

Operational Bottlenecks

Smart Intralogistics Solution

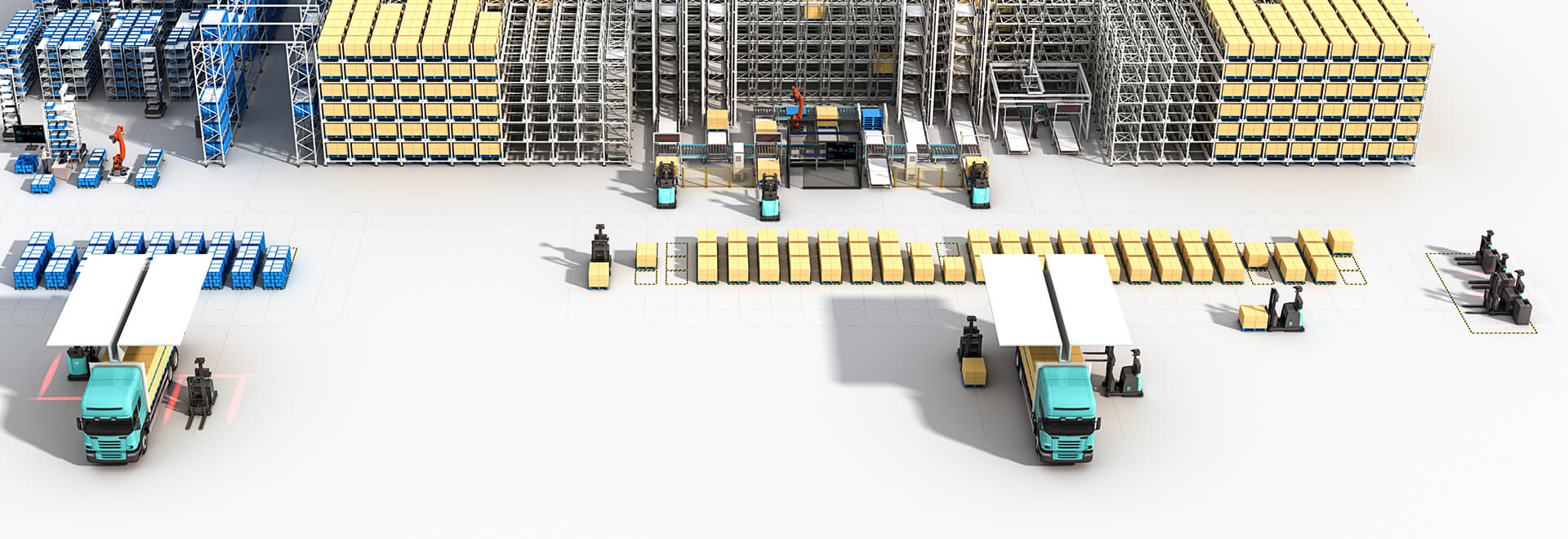

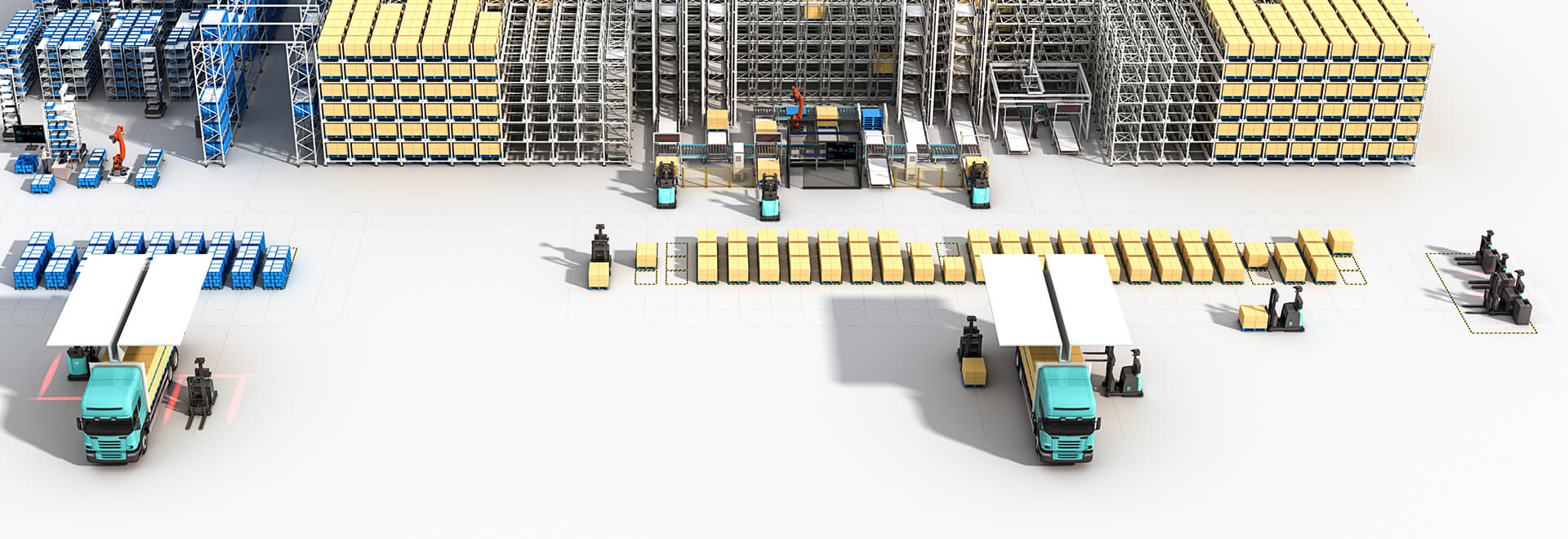

Implementing an intelligent intralogistics system based on the counterbalanced AGV forklift MW-SE20 as the hardware platform & achieving full-process automation from empty frame loading to scrap unloading into the storage area

Loading of Empty Frames

Inter-process Transfer

Inbound of Full Frames

🌟

Highlights of the Solution

By introducing Multiway Robotics' flexible in-factory intelligent logistics solution, the entire flow of equipment and information within the plant is seamlessly integrated. The self-developed WCS (Warehouse Control System) enables unified management of upstream and downstream equipment, including integration with systems such as chip compactors and PAD terminals. The RCS (Robot Control System) autonomously plans optimal routes, enabling efficient multi-vehicle collaboration to support 24/7 continuous production on site.

With integrated hardware and software delivery, Multiway Robotics not only meets the heavy-load handling demands of factories but also reduces labor costs, enhances inbound and outbound logistics efficiency, and maximizes economic benefits—driving the digital transformation of enterprise operations. To date, Multiway has served over 700 large enterprise clients across more than 20 industries, including food, pharmaceuticals, new energy, automotive, machinery manufacturing, and cold chain logistics.