Case Introduction

Under the new wave of consumption upgrade, the automotive industry's demand for personalized and flexible production manufacturing is becoming increasingly urgent. Multiway Robotics provides a comprehensive intelligent logistics solution for an automotive parts manufacturing enterprise, helping the enterprise in rapidly responding to market and production changes to achieve more efficient production capabilities.

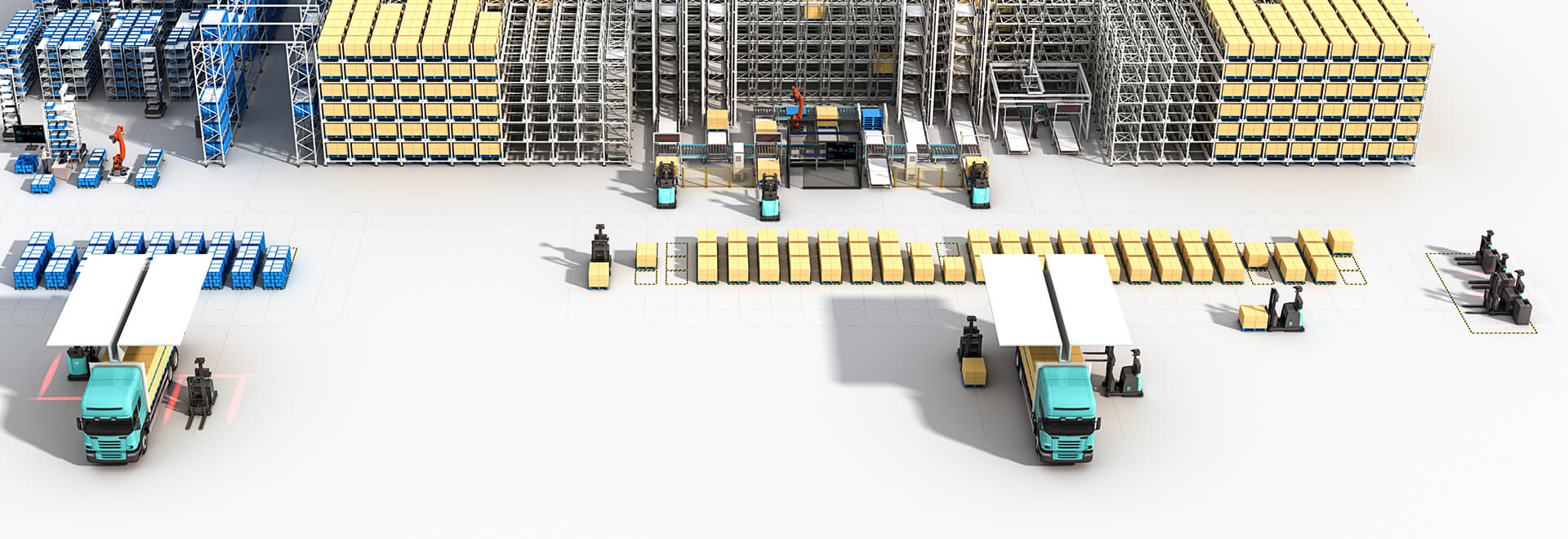

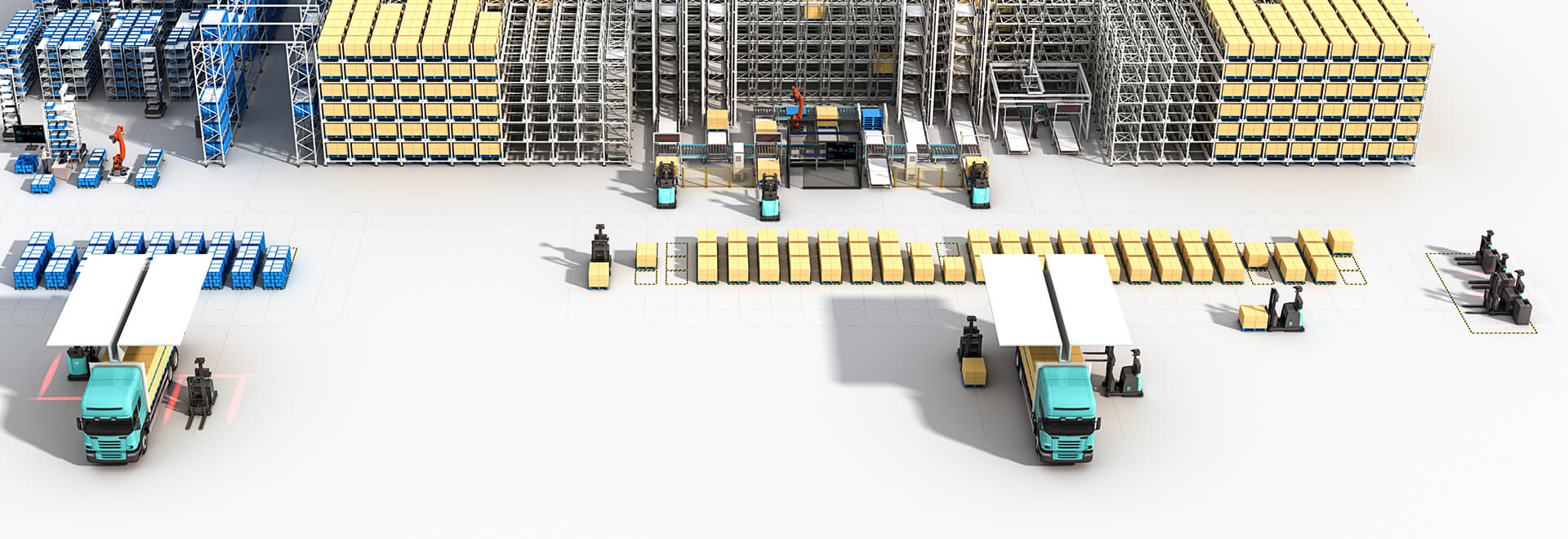

Comprehensive Intelligent Logistics Solution

Creating an Efficient and Smooth Material Distribution System

The automotive industry is a typical discrete manufacturing sector, characterized by a highly dispersed supply chain, complex production processes, and intricate product structures. As a large-scale automotive parts manufacturer, the client typically needs to store a large quantity of raw materials and semi-finished parts, requiring high standards in material management. With different production workshops located at considerable distances, manual material handling is time-consuming and labor-intensive.

By introducing Multiway Robotics' comprehensive intelligent logistics solution, smart handling replaces traditional manual labor, not only saving labor costs but also ensuring efficiency in material loading/unloading. This approach also achieves high-efficiency, high-quality warehouse and logistics management.

Scope of Operation

Automated Storage and Retrieval System (AS/RS), Picking Area, Distribution Ready Area, AB/RJ Factory, Charging Area

Handling Process

Tasks are assigned through a PDA. Upon receiving storage instructions, the RCS system then schedules unmanned forklifts to handle turnover transportation in areas like the AS/RS conveyor line, finished goods handover area, and picking area.

Project Benefits

The introduction of the unmanned forklift system achieves long-distance material transportation across factory areas and automates storage/picking processes.

Long-Distance Automated Transportation Across Various Areas

Enhancing Overall Efficiency in Handling and Distribution

Multiway Robotics introduced the "pallet stacker MW-L16" as hardware products, enabling efficient cross-factory material handling and inventory visual management from the AB factory and AS/RS to the RJ factory. This initiative drives the development of intelligent production and warehousing logistics systems.

The project, involving outdoor operational environments, brings a flexible, efficient, and safe integrated solution to the client without significant environmental modifications. It achieves efficient indoor and outdoor full-scene linkage, comprehensively enhancing delivery efficiency.

Integrated Hardware and Software Delivery

Full-Scale Logistics Automation and Data Visualization

With self-developed WCS (Warehouse Control System), the entire upstream and downstream equipment are interconnected. Unmanned forklifts connect with automated storage/picking systems, barrier gates, automatic doors, and other automated devices, achieving 100% unmanned logistics among various areas. Additionally, integration with the client's cloud system automates the update of material information, leading to concentrated storage, efficiency improvement, and reduced labor costs.

Simultaneously, the self-developed RCS (Robot Control System) enables optimal route planning for unmanned forklifts, intelligent traffic dispatching, autonomous obstacle avoidance, and automatic charging, effectively improving handling efficiency. Users can access task information, vehicle status, fault alarms, and other critical information through the system interface, maintaining real-time awareness of operational dynamics.