Case Introduction

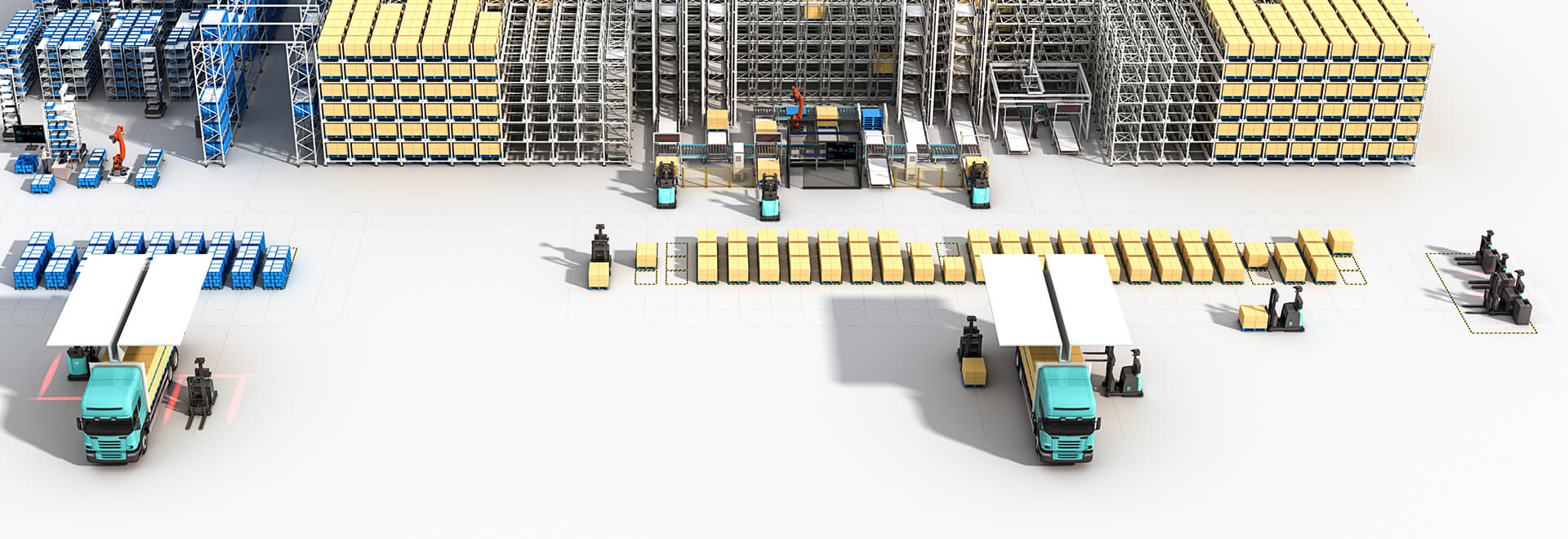

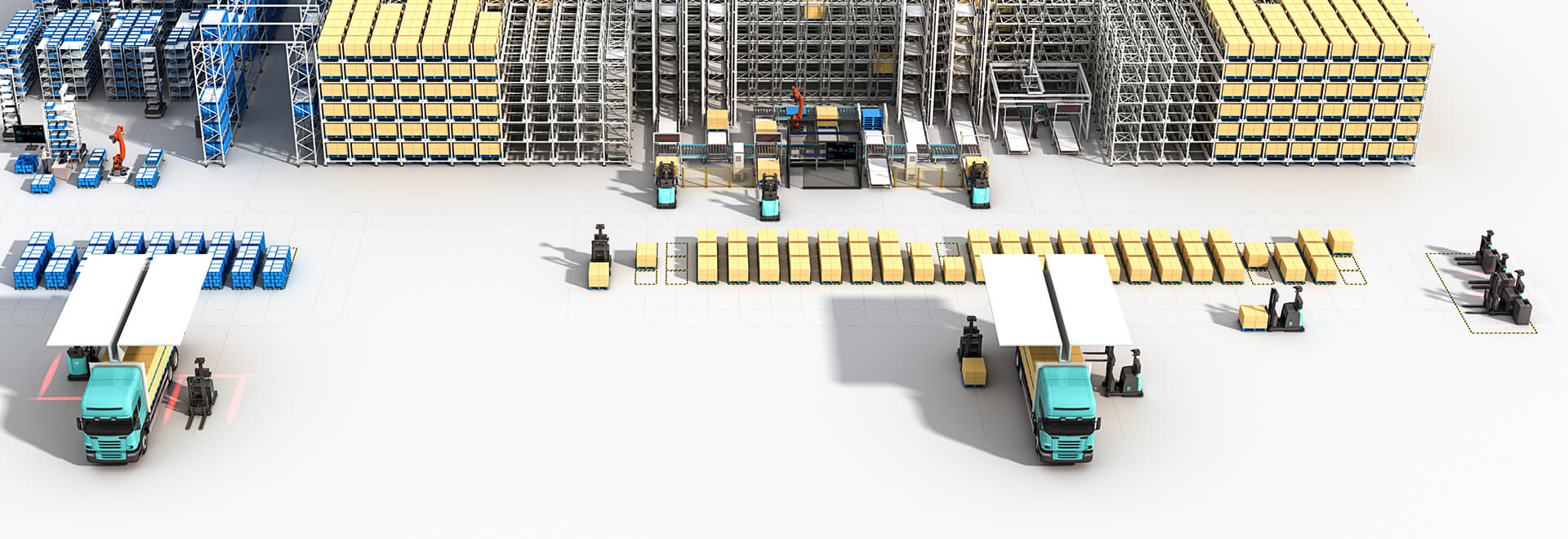

The customer is a large modern enterprise mainly focused on mechanical basic components and automotive components. As an absolute leader in the domestic industry, the enterprise continuously accelerates industrial technology upgrades and cooperates with Mulitiway Robotics in the intelligent logistics process. By utilizing advanced robot equipment and industry solutions, the enterprise achieves automatic inbound and outbound transportation of finished products in the warehouse.

Efficient collaboration across different vehicle models

WeFront X20+The VNA truck MW-K16

The warehouse adopts a six story crossbeam style shelf for storage, with a storage capacity of nearly 5000 locations. With the support of the RCS scheduling system, multiple vehicles work efficiently together, independently plan the optimal path, and the handling efficiency can reach 70 pallets per hour.

WeFront X20 is responsible for transporting the weighed finished products from the temporary storage area to the packaging area, and then transporting the packaged finished products from the storage area to the front dock of the warehouse.

The VNA truck MW-K16 is responsible for transporting packaged finished products from the front dock to the finished product warehouse shelf, or transporting finished product warehouse materials to the front dock.

Extremely narrow roadway,

6-story shelves for high-level access

The warehouse effectively alleviates the problem of insufficient storage space. The VNA truck MW-K16 has functions such as tray posture recognition and high-level space detection. Through 6-layer shelves and high-density three-dimensional storage, it effectively utilizes spatial resources, saves ground space, and improves the storage capacity of the factory

The VNA truck MW-K16 can lift up to 9000mm, with a narrowest aisle width of only 1750mm. The vehicle body does not need to turn, and through 180 ° rotation and left and right lateral movement of the fork, it can achieve efficient stacking and loading and unloading of goods on both sides of the aisle, in narrow passages, floors, elevated warehouses, and other places

▲Automatically charge after the task is completed