Multiway’s lightweight unmanned forklift Wefront X20 helps improve the inbound and outbound efficiency of the textile factory.

Video

Video

Case Introduction

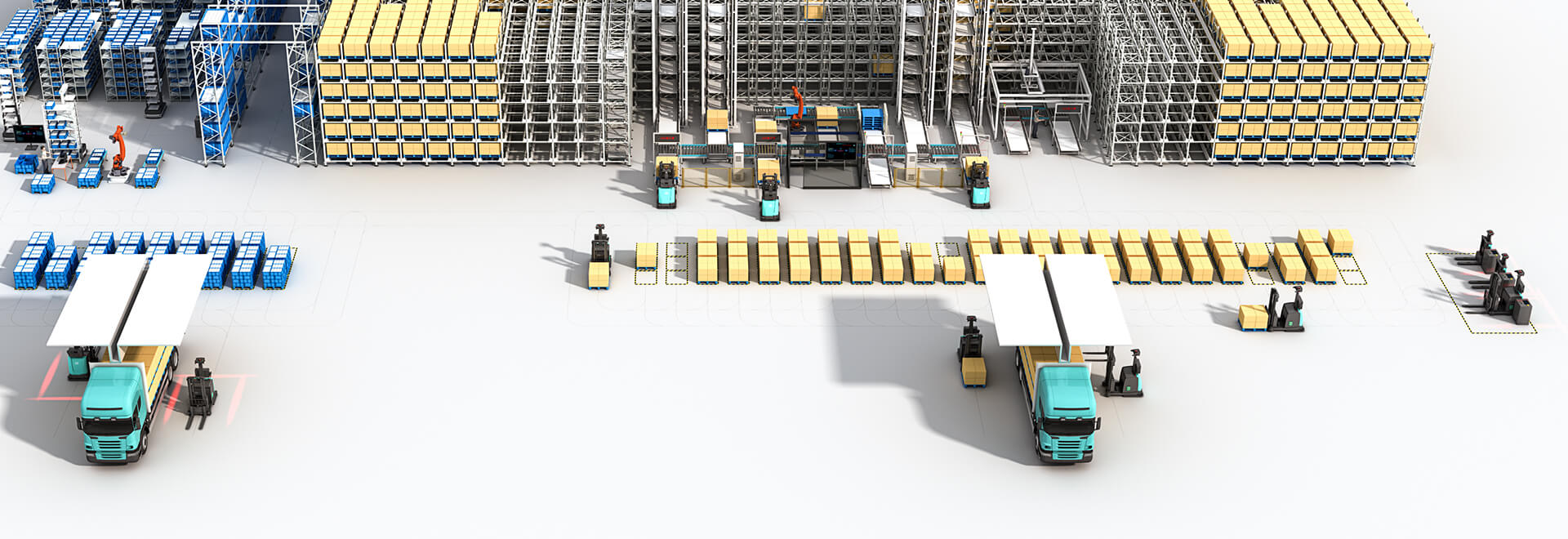

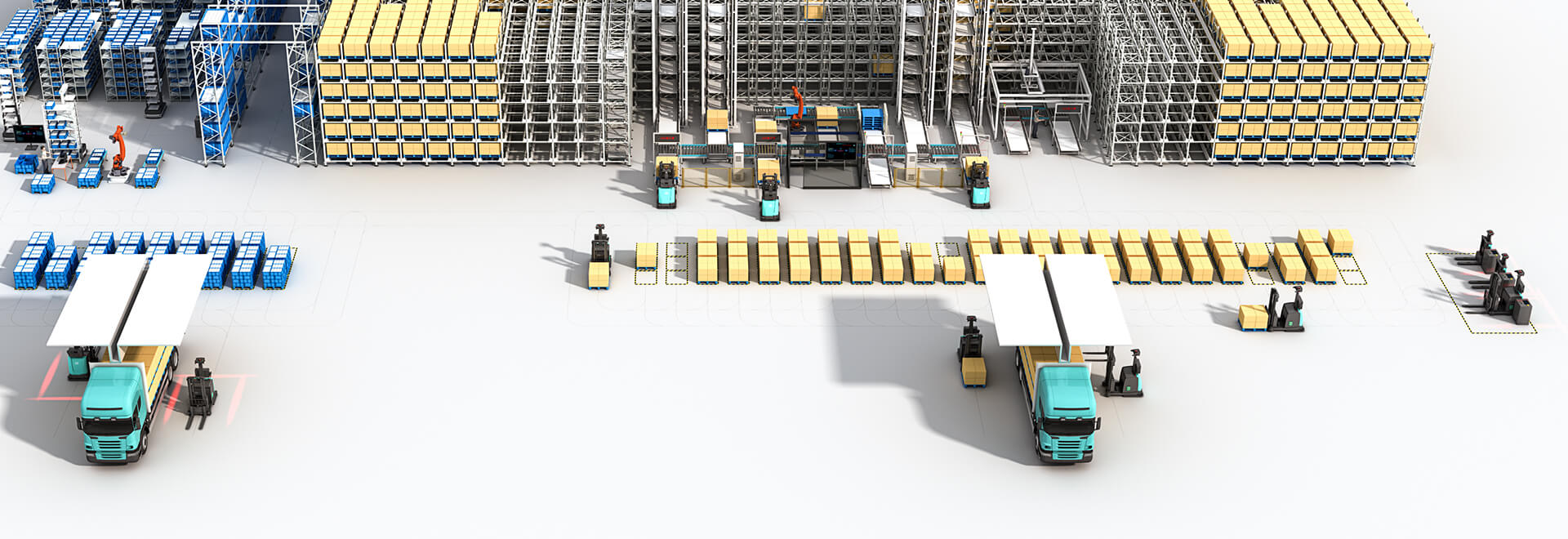

Recently, Multiway Robotics has successfully assisted a large-scale textile fiber production company to achieve intelligent logistics throughout the entire process. The project has deployed the new form AGV forklift Wefront X20, combined with the scheduling & dispatching system RCS, the equipment control system WCS. The factory's original material handling methods have been optimized and upgraded. Its work efficiency has been greatly improved.

X20 Product Introduction

Ultra-light: requires minimal floor load-bearing capacity.

Multi-capable: supports operation across multiple areas and floors.

Ultimate performance: fast, agile, and modular for ultra-rapid deployment.

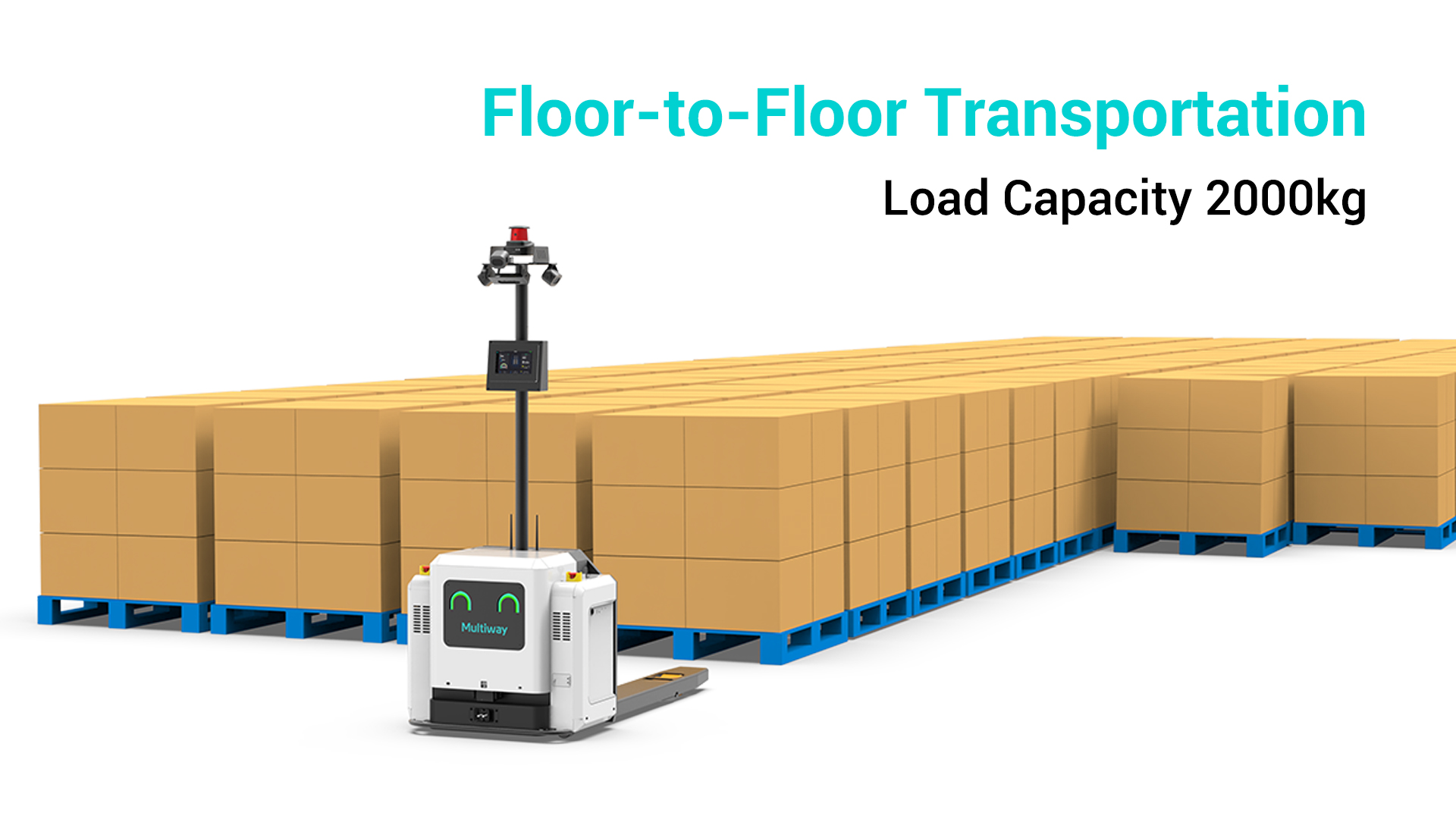

Flat Transportation

Load capacity: 0–2000 kg

Suitable for flat-handling scenarios such as high-level racking, multi-layer ground stacking, and production line docking & collaboration.

Elevator-enabled Multi-Floor Operation

Self-weight: 460 kg

Supports seamless integration with elevator control systems to enable elevator riding and cross-floor transportation.

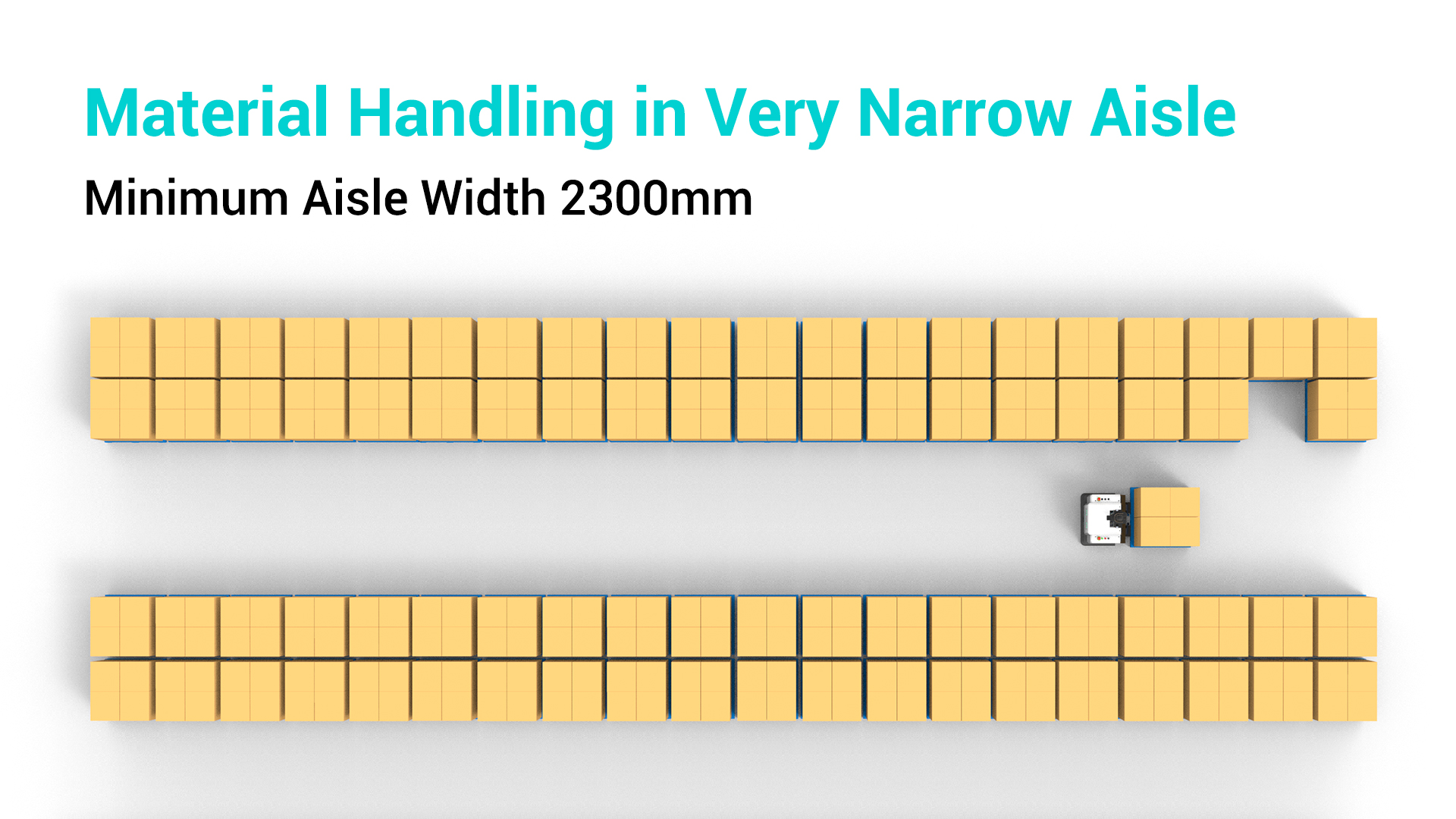

Narrow-aisle Handling

Aisle width: 2300 mm

Saves aisle space and significantly improves space utilization.