Efficiency up! Multiway Robotics supports the logistics automation upgrade of a major rare-earth energy enterprise in Baotou, Inner Mongolia.

Video

Video

Case Introduction

As one of China’s key rare-earth production regions, Baotou in Inner Mongolia boasts abundant rare-earth mineral resources and a well-developed rare-earth industry. With global demand for rare-earth resources continuing to rise, rare-earth energy enterprises are facing dual challenges: improving production efficiency and reducing costs. Logistics automation and informatization, as crucial approaches to enhancing competitiveness, are increasingly being adopted and promoted among rare-earth energy enterprises in Inner Mongolia.

As a leading enterprise in the industry, this energy company has long been committed to the mining, processing, and sales of rare-earth resources. However, as its business scale continues to expand, traditional logistics methods can no longer keep pace with rapidly growing production demands. The company urgently needs to optimize its logistics processes through technological upgrades.

Based on this, during the internal project initiation and promotion process, both parties held multiple rounds of discussions, including calculating the required number of unmanned forklifts, solution planning, and expected ROI evaluation. Ultimately, the company chose to collaborate with Multiway Robotics.

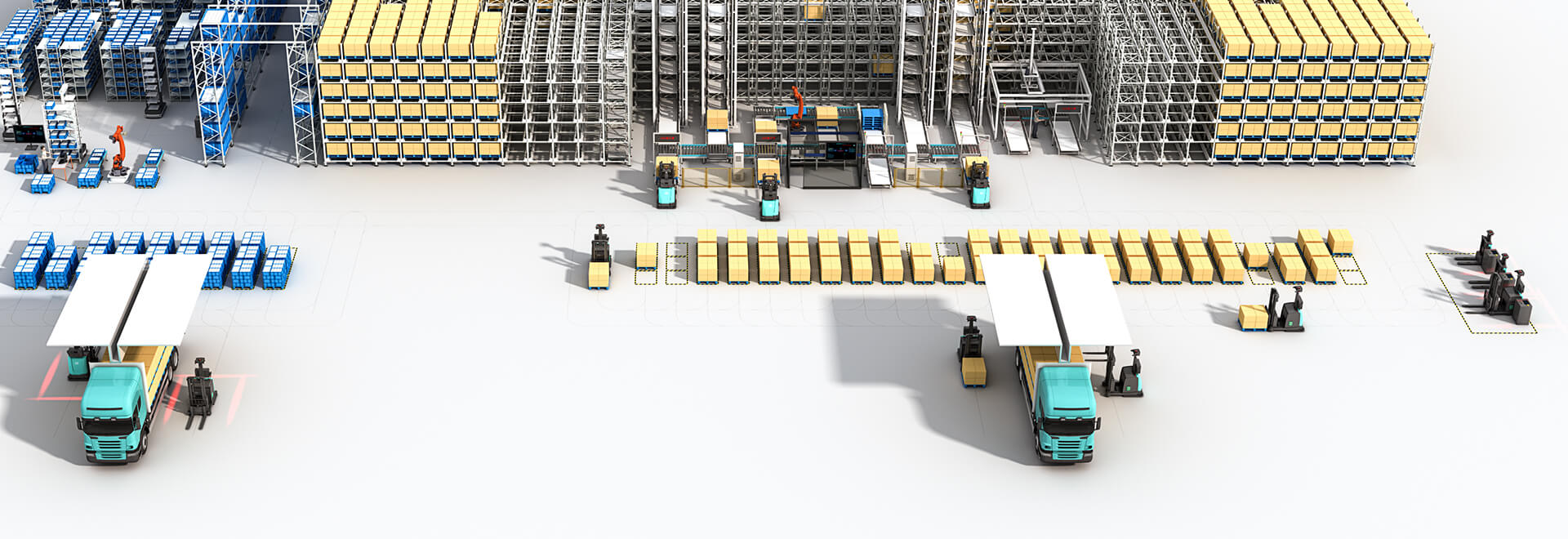

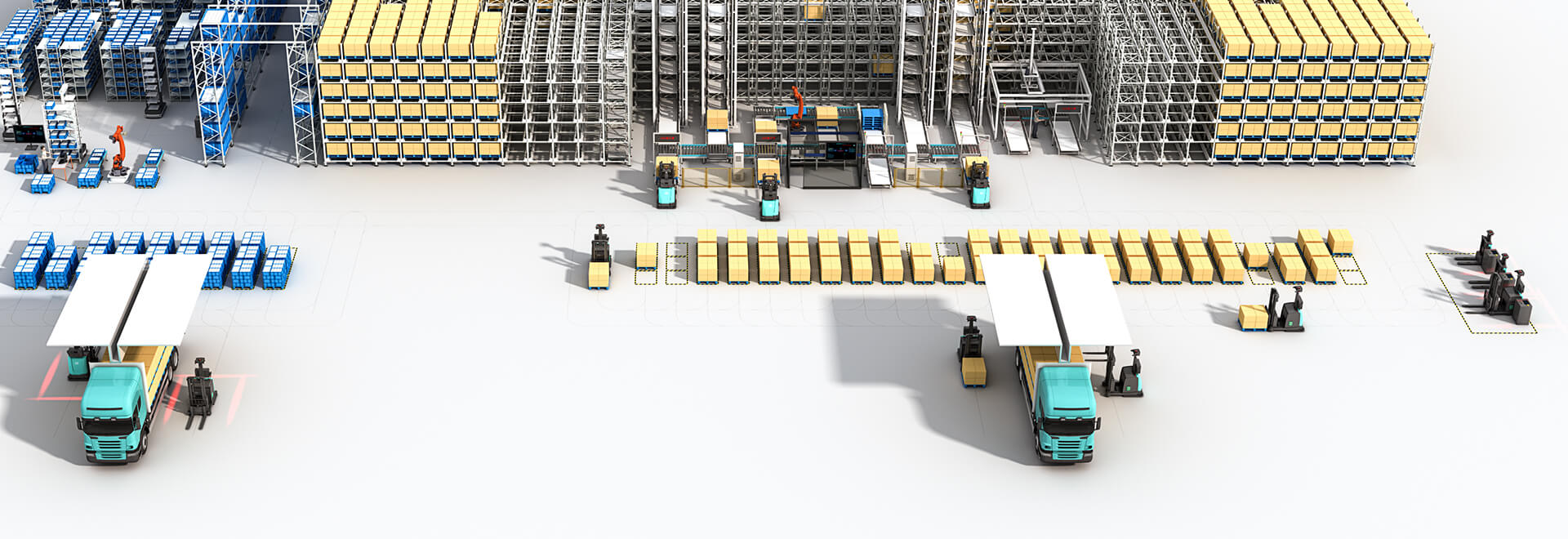

Together, they implemented comprehensive logistics automation and digital information board upgrades across the following areas:

Kiln line workshop (semi-finished product unloading, weighing, lid removal and covering operations)

Outdoor area (logistics corridor from the kiln line to the depalletizing workshop)

Buffer zone (buffer storage area)

Depalletizing workshop

Finished goods temporary storage area (handover area for palletized finished goods entering the warehouse)

Finished goods warehouse (storage area for finished products)

During the technology selection stage, the company compared various automated logistics solutions and ultimately chose to adopt Multiway Robotics' integrated intelligent logistics solution of both hardware and software.

The hardware includes:

MW-SL14 stacker unmanned forklift

MW-ST20 pallet unmanned forklift

The software systems include:

WMS (Warehouse Management System)

RCS (Robot Control/Scheduling System)

WCS (Warehouse Control System)

Horizons vision system

Task Call

Kiln line, weighing, lid removal, lid covering, depalletizing equipment: Loading and unloading calls are triggered through signal integration between both systems.

Manual palletizing: Party A initiates loading and unloading calls via Party B’s button box.

Temporary storage area: Party B’s Horizons vision system automatically monitors empty pallets and vacant storage locations, triggering calls accordingly.

System / Equipment Integration

The handling process involves 3 automatic doors, 2 kiln lines, 2 weighing devices, 2 lid removal devices, 2 lid covering devices, and 2 depalletizing devices. The Multiway Robotics WCS equipment management system integrates the information flow of these devices, enabling seamless interaction between the equipment and unmanned forklifts.

Material Handling Process

Kiln line inbound/outbound → Handover station: Handling is performed by the MW-ST20 light pallet unmanned forklift.

Handover station → Buffer zone → Depalletizing line: Handling is performed by the MW-SL14 stacker unmanned forklift.

Handover station → Buffer zone → Depalletizing line: Handling is performed by the MW-ST20 light pallet unmanned forklift.

After the automated logistics system was put into operation, material handling and storage efficiency increased by over 30%.

By reducing manual operations, the company can save several million yuan in costs annually.

The use of automated equipment has significantly reduced the rate of workplace safety incidents.

Automated logistics has reduced energy consumption, meeting the requirements for sustainable development.