Flagship Case | Full-Process Unmanned Operations: Multiway Robotics’ Three-Way Smart Forklift Solution Enables Intelligent Upgrade of a European High-Bay Warehouse

Video

Video

Case Introduction

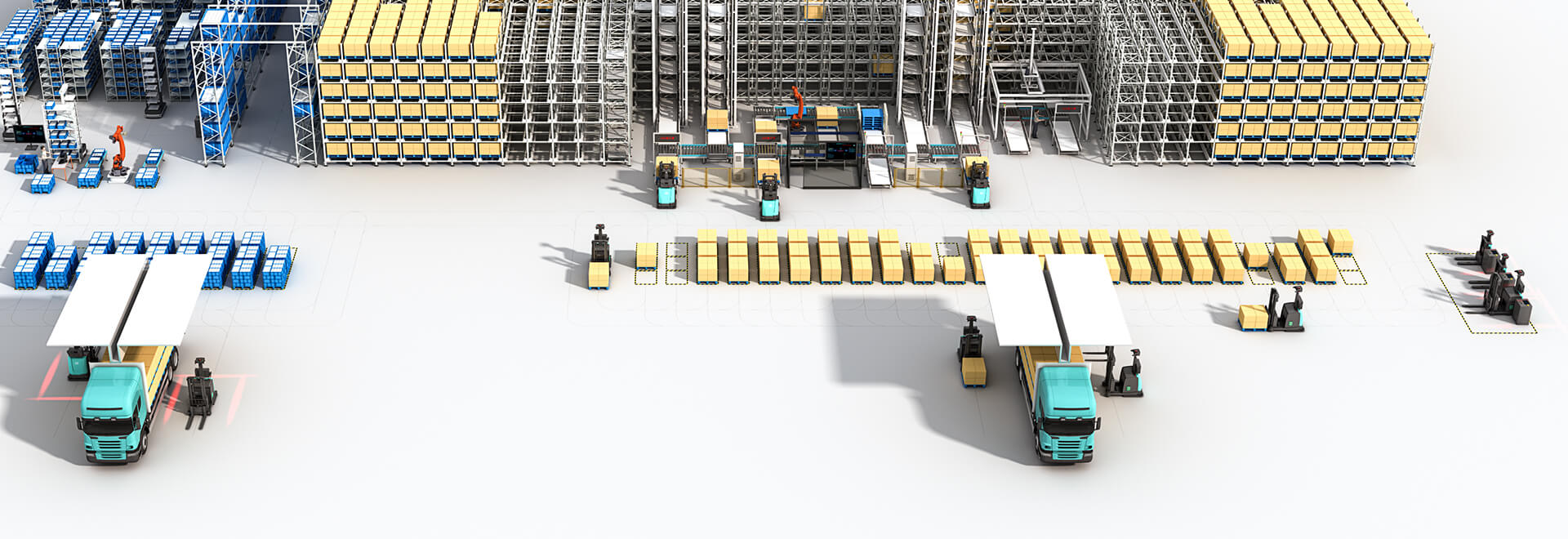

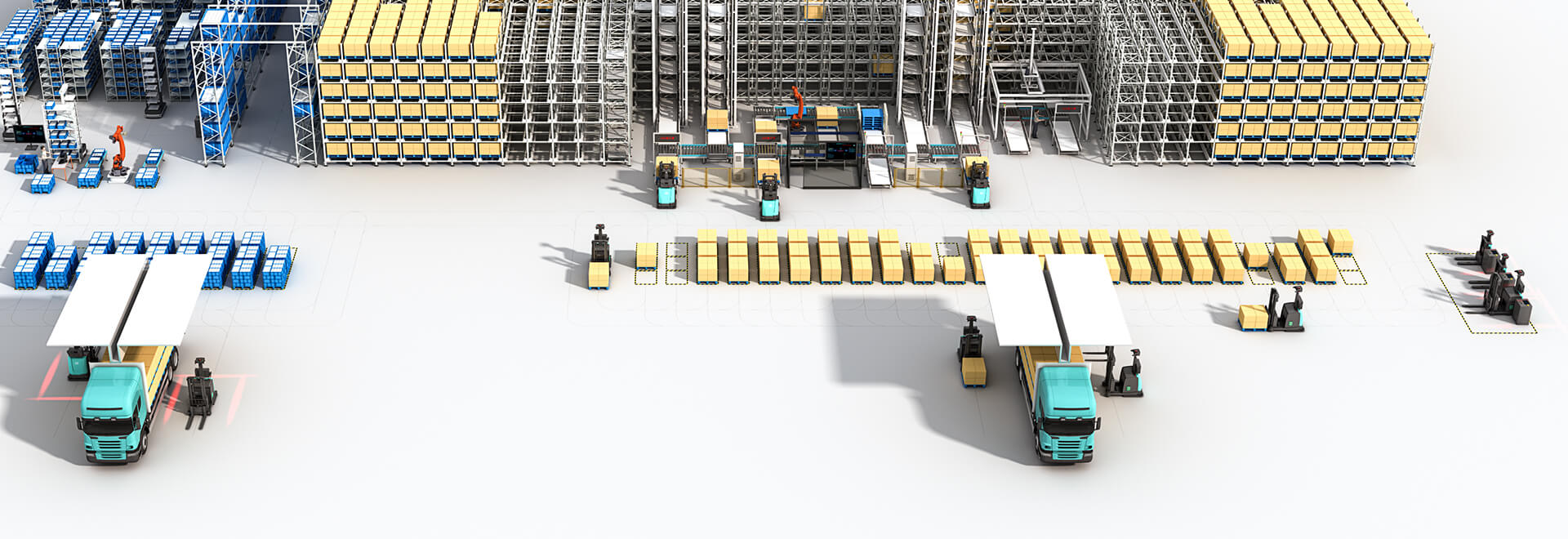

Against the backdrop of ongoing global supply chain restructuring, the demand for warehouse automation, safety, and efficiency in Europe is growing rapidly. Recently, Multiway Robotics successfully completed a high-density high-bay storage project for a well-known import and export enterprise in the Mediterranean region. By deploying the three-way autonomous forklift MW-K16, the WMS warehouse management system, and the RCS scheduling system, the company has established an intelligent warehouse benchmark capable of stable 24/7 operation.

The project has significantly improved warehouse operational efficiency, increasing the high-bay handling rate to a stable 10–15 pallets per hour, and boosting operational efficiency by more than 30% compared to manual processes. At the same time, it once again validated Multiway’s global delivery capability and product maturity, from solution design to system implementation.

Project Background

Multiway Robotics

The customer’s core warehousing center adopts a narrow-aisle high-bay racking layout, achieving extremely high space utilization, but it has also resulted in long-standing challenges:

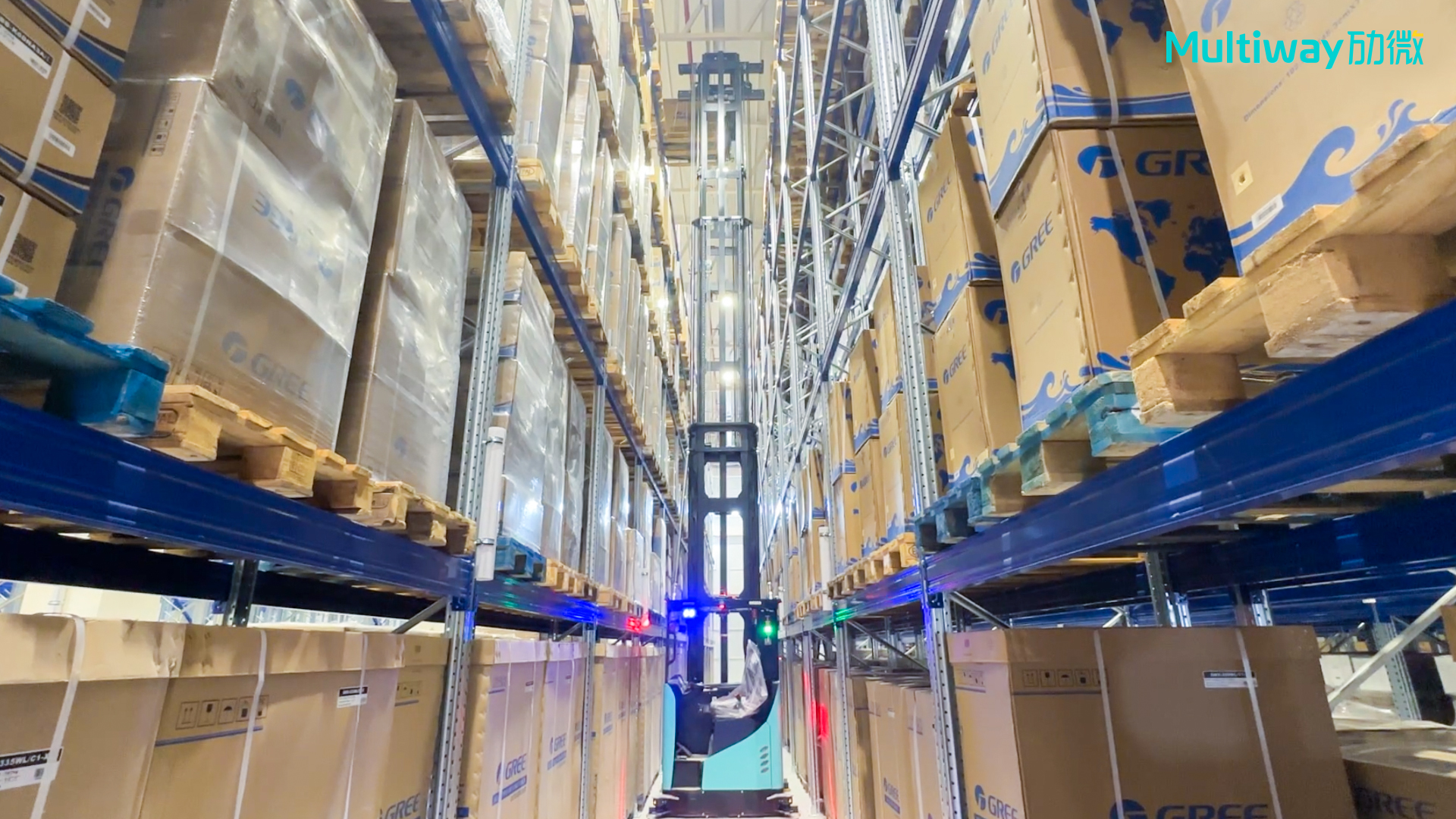

The aisle width is less than 2,000 mm, making manual forklift operation difficult and posing high safety risks;

The high-bay area exceeds 10 meters in height, and manual operation efficiency is easily affected by workers’ experience levels;

Inventory relied on manual data recording, resulting in delayed information and frequent errors;

With business volume continuously increasing, it became difficult to scale operations relying solely on manual labor.

To achieve the goals of improving efficiency, reducing risks, and enhancing digital transparency, the customer decided to implement unmanned products and systems, realizing full automation of inbound, outbound, and high-bay storage operations.

Multiway Solution

Multiway Robotics

For the customer’s high-density high-bay storage scenario, Multiway provides an integrated smart logistics solution centered on three-way autonomous forklifts, combining both hardware and software:

01. Hardware Product: Three-Way Fork Autonomous Forklift MW-K16

High-lift capability reaches 11 meters, covering all rack levels in the facility.

Operates in narrow aisles of 1,750 mm, using laser navigation and an end-point vision system to achieve high-precision picking and placing.

Supports automatic charging and 24/7 operation, meeting the demands of high-frequency inbound and outbound operations.

The equipment performs all core operations throughout the project, including inbound, outbound, and high-bay storage, making it a key asset for achieving a fully unmanned warehouse.

02. Software Systems: WMS Warehouse Management System × RCS Scheduling System

To meet the customer’s high-frequency logistics requirements, this project deployed Multiway’s self-developed WMS warehouse management system and RCS scheduling system.

Warehouse Management System (WMS)

Visualizes storage locations, inventory, and goods status.

Intelligently allocates storage locations based on goods height, automatically improving high-bay space utilization.

Inbound and outbound tasks are automatically generated and linked with AGV scheduling.

Integrated with ERP to enable two-way synchronization of orders, batches, and inventory information.

RCS Scheduling System

Displays AGV positions, tasks, battery levels, and statuses in real time.

Automatically plans optimal routes, dynamically avoids obstacles, and enables continuous operations.

Intelligently schedules autonomous forklifts based on task priority and distance for efficient coordination.

Automatically returns to the charging station when battery is low, ensuring stable operational rhythm.

Project Outcomes

Multiway Robotics

Storage density increased by 30%+

Inbound/outbound handling rate stabilized at 10–15 pallets/hour

Inventory accuracy improved to 100%

On-site human-vehicle risk reduced to 0

Warehouse operations fully digitalized and visualized

Full-process unmanned high-bay operations

Global Delivery Capability

Multiway Robotics

From solution design and product manufacturing to on-site implementation and customer training, Multiway Robotics has built a mature system architecture and a global service capability, enabling high-standard deployment across different countries and diverse business environments. The successful implementation of the Mediterranean project demonstrates Multiway’s professional delivery capability and technical reliability in cross-regional, multi-scenario projects, serving as another benchmark case for Multiway’s continued expansion in Europe and broader overseas markets.