Multiway Robotics Empowers “Tobacco Enterprise” to Accelerate and Enhance Intralogistics Performance

Video

Video

Case Introduction

The shift from manufacturing to being closer to the sales market has become an inevitable trend. To meet increasingly diverse and customized end-market demands, traditional tobacco enterprises are gradually transforming into service-oriented manufacturing businesses, requiring high adaptability and agility to respond to market dynamics. This transition presents new challenges for the operational efficiency of enterprise logistics.

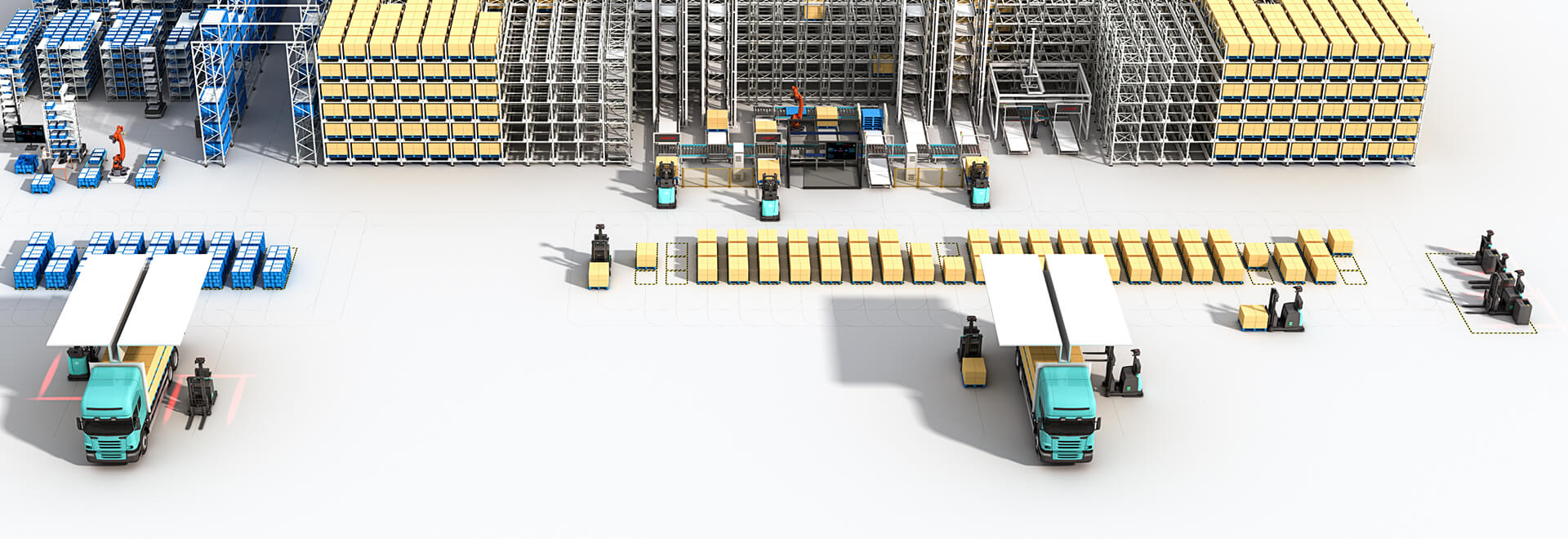

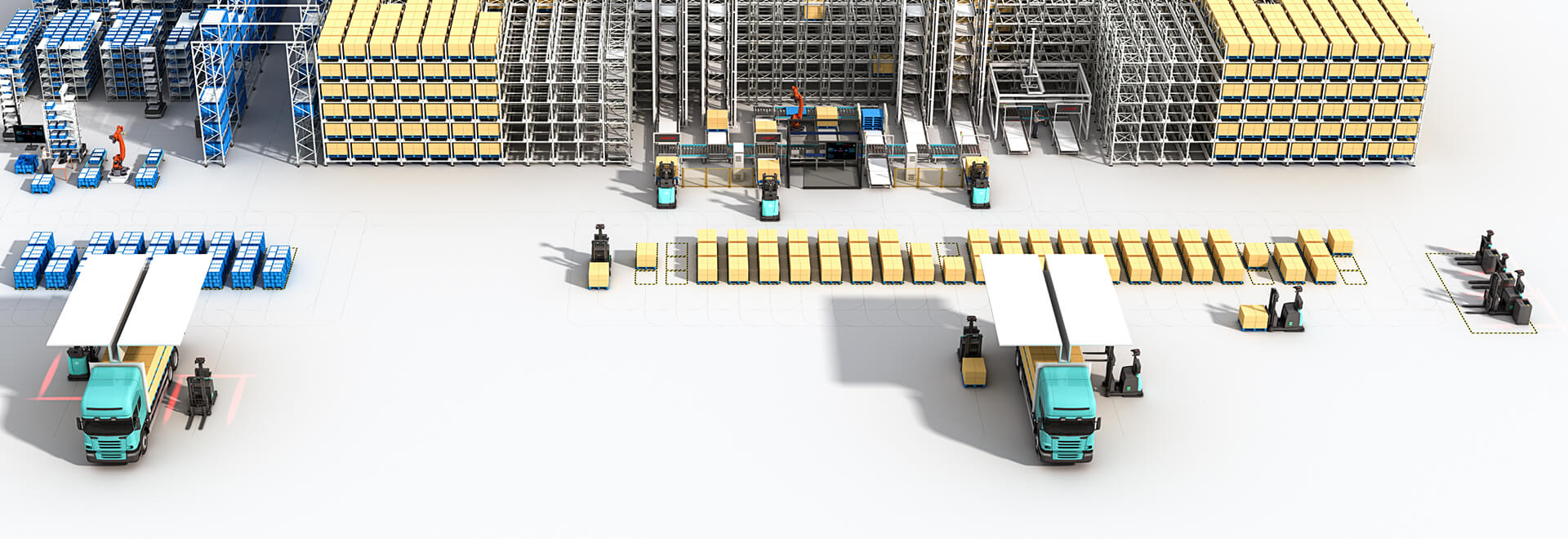

A tobacco production base located in Shandong leverages Multiway's robotics technology to build a high-efficiency, agile intralogistics system. The intelligent and efficient unmanned forklift solution helps the enterprise address issues associated with traditional handling models, such as labor management and goods information management, enabling the company to keep pace with the development of the new era.

﹀

﹀

﹀

Customer Pain Points

By introducing the "MW-SL14 autonomous stacker forklift" as the core hardware and integrating it with the WMS warehouse management system, WCS equipment control system, and RCS scheduling system, the enterprise deploys a holistic smart logistics solution that combines software and hardware. This enables full-process informatization and intelligent logistics integration services.

MW-SL14 Autonomous Stacker Forklift

Max Lifting Height:3500mm

Rated Load:1400kg

Let's take a look at the business scenarios and key requirements.

The handling vehicle is a material cart with a wheel height of 190 mm. In inbound and outbound scenarios, it is compatible with stacker-type autonomous forklifts that have sufficient lifting capacity and are suitable for narrow indoor aisles and high-rack handling.

In addition, the MW-SL14 stacker-type autonomous forklift is one of Multiway Robotics' standard models, offering strong cross-scenario adaptability and significant economies of scale.

Handling Process

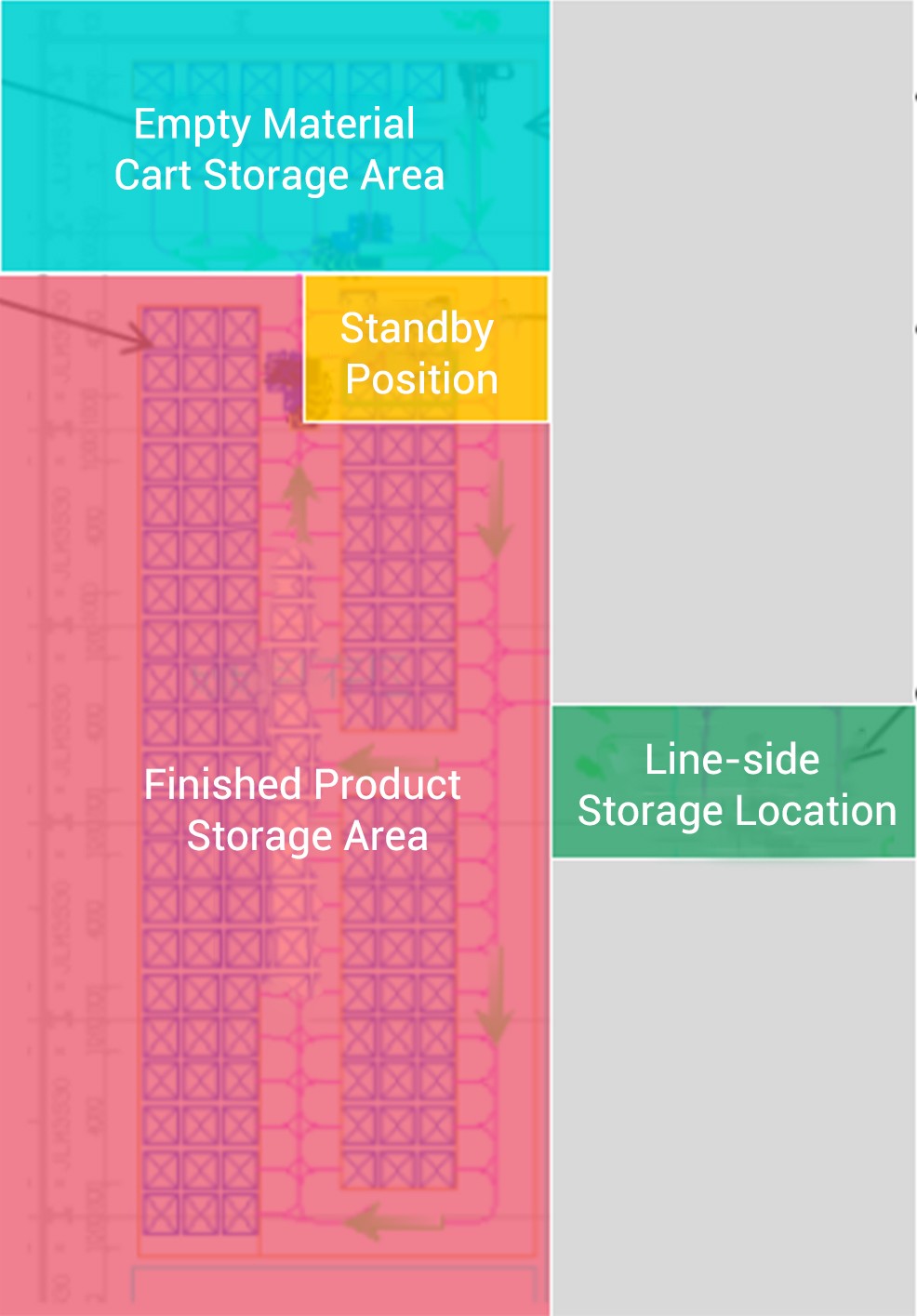

The WMS automatically analyzes handling orders to match storage locations and issues handling tasks. The autonomous forklift moves to the designated location, transporting goods from the line-side storage to the finished goods storage area, or moving empty carts from the empty cart storage area to the line-side storage location.

By implementing the autonomous forklift system, automatic inbound and outbound of goods and automatic loading/unloading for production lines are achieved.

Integrated Hardware and Software Delivery#

Make Management More Transparent and Efficient

The integrated hardware and software smart logistics solution connects all logistics, information, and equipment flows across the tobacco factory. It enables traceability of goods data, allowing real-time monitoring of logistics progress and anomaly detection, making management more transparent, convenient, and efficient.

The WMS warehouse management system supports a top-down overview of storage locations, allowing intuitive visualization of location distribution, current status, and inventory information. It also provides basic information management, vehicle management, material management, inventory management, and more, assisting the factory with goods receipt and dispatch, stocktaking, and report generation.

Efficient Human-Vehicle Collaboration#

Covers Fragmented and Complex Scenarios

In areas such as line-side storage and finished goods storage, there is mixed traffic of humans and vehicles. The autonomous forklift is equipped with pallet pose recognition, enabling it to automatically identify the position and orientation of goods and accurately pick and place them even if the manual placement is slightly off.

In addition, the vehicle is equipped with multiple safety features, including 360° laser obstacle avoidance, audible and visual alarms, and collision protection strips, ensuring safety during mixed human-vehicle operations. Through the RCS scheduling system, vehicle status is monitored in real time, enabling task dispatching and traffic management, which guarantees accuracy and efficiency in inbound/outbound operations and material handling.

Multiway Robotics' products and solutions are widely applied across industries such as new energy, automotive, food, pharmaceuticals, and 3PL. The company has served over 300 enterprise clients, including more than 20 industry leaders, earning broad recognition from customers.

Through large-scale deployment in complex scenarios—such as high-level storage and retrieval, coordinated loading and unloading with vehicles, human-vehicle collaboration, yard management, correcting misaligned placements, and cage stacking—Multiway Robotics delivers continuous value to clients via modular product deployment and platform system delivery.