Collaboration between Multiway Robotics and Famous Coating Manufacturing Enterprises for Intelligent Logistics Upgrade

Video

Video

Case Introduction

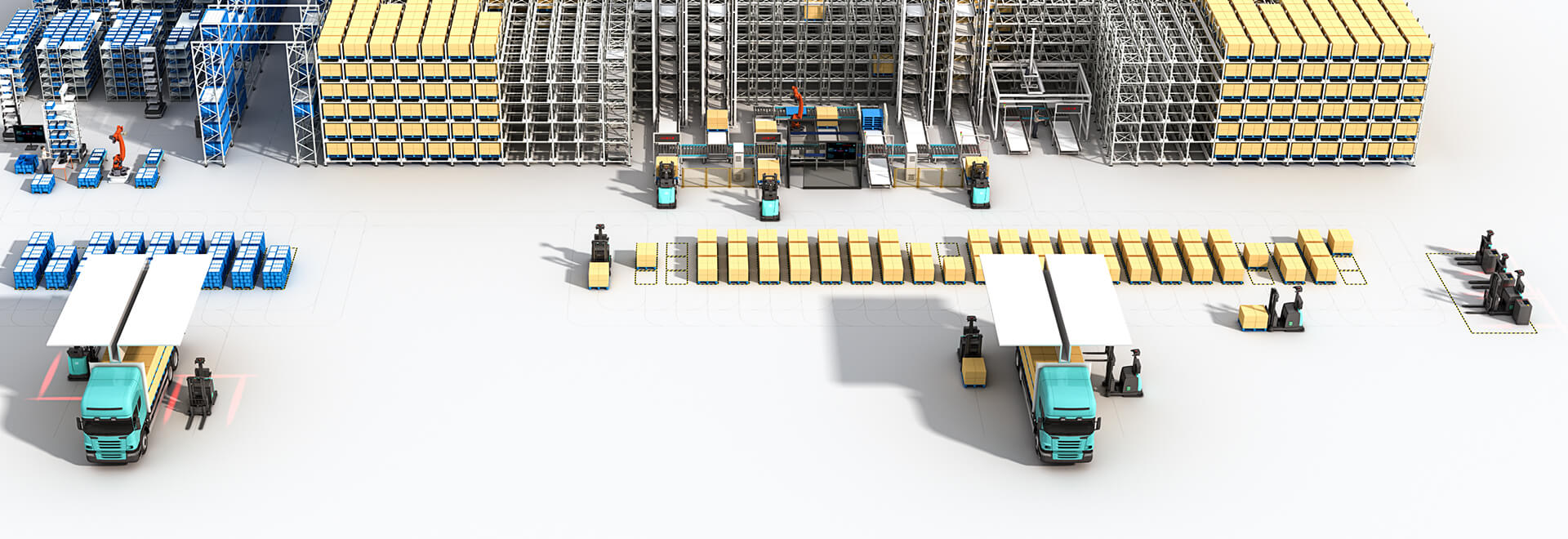

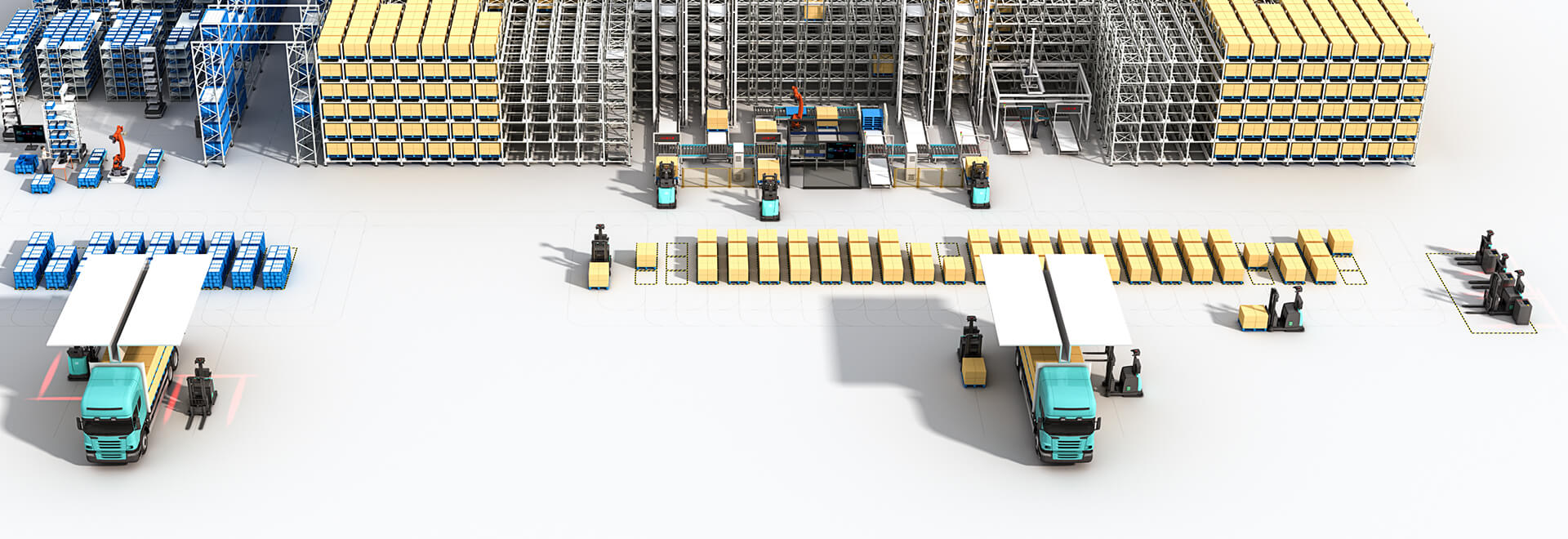

The development of the paint industry is approaching maturity, and the current traditional development model is gradually restricting the healthy development of the paint industry. In order to enhance the competitiveness of the enterprise and achieve cost reduction and efficiency increase, this well-known coating manufacturing enterprise located in Foshan has chosen to cooperate with Maiwei Robotics. By deploying a highly flexible unmanned forklift solution, it greatly improves the efficiency of inbound and outbound operations and achieves digital logistics management.

Customer pain points

1. Traditional manual handling has high labor intensity and low collaborative efficiency.

2. The information of warehouse goods in and out is not transparent, and the efficiency of finding goods is low.

3. Difficulty in recruiting and high labor costs, requiring better cost reduction and efficiency improvement.

4. There is powder in the workshop, and the environment is harsh, causing significant harm to the body.

Solution

Introducing an intelligent logistics solution using the "Forward Moving Unmanned Forklift MW-R14" as the hardware carrier, combined with the WMS warehouse management system, WCS equipment control system, and RCS scheduling system, to achieve the full process automation of material handling in paint manufacturing factories, from metal powder storage to semi-finished product storage to finished product storage, greatly improving inbound and outbound efficiency, saving labor costs, and helping enterprises reduce costs and increase efficiency.

Highlights of the plan

The project site involves indoor and outdoor scenarios, and from indoor to outdoor environments, unmanned forklifts need to deal with more complex problems, such as outdoor navigation and positioning, weather emergencies, etc. The forward moving unmanned forklift MW-R14 relies on advanced laser navigation positioning, adaptive complex environment, and efficient indoor and outdoor linkage operation.

In addition, the forward moving unmanned forklift MW-R14 has a lifting function, greatly improving the utilization of warehouse space. Multiple robots work on the same site and can independently plan the optimal path, intelligent traffic management scheduling, and avoid situations such as locking and traffic congestion.

Automatic door docking

Goods loading and unloading

Indoor and outdoor passage

Plan effectiveness

1. By introducing an unmanned forklift system, goods can automatically enter and exit the warehouse, and robots can operate unmanned 24 hours a day, greatly reducing enterprise management costs and improving the overall efficiency of transportation.

2. Integrated delivery of software and hardware, achieving traceability and tracking of goods data, allowing enterprises to constantly monitor logistics progress and monitor anomalies, making management more transparent, convenient, and efficient.

3. Provide an open WCS system standard interface, connect the entire upstream and downstream equipment, connect unmanned forklifts with automatic doors, conveyor lines, etc., efficiently dispatch vehicles, and ensure orderly logistics on site.