Case Study | Enhancing Multi-Floor Logistics Efficiency with the X20 Autonomous Forklift in Electronics Manufacturing

Video

Video

Case Introduction

Driven by the third wave of semiconductor industry relocation and strong national policy support, the electronic components industry in China is entering a phase of accelerated domestic substitution and structural upgrading. As market demand continues to grow and competition intensifies, electronic component manufacturers are transitioning from low-end production toward mid- and high-end manufacturing models.

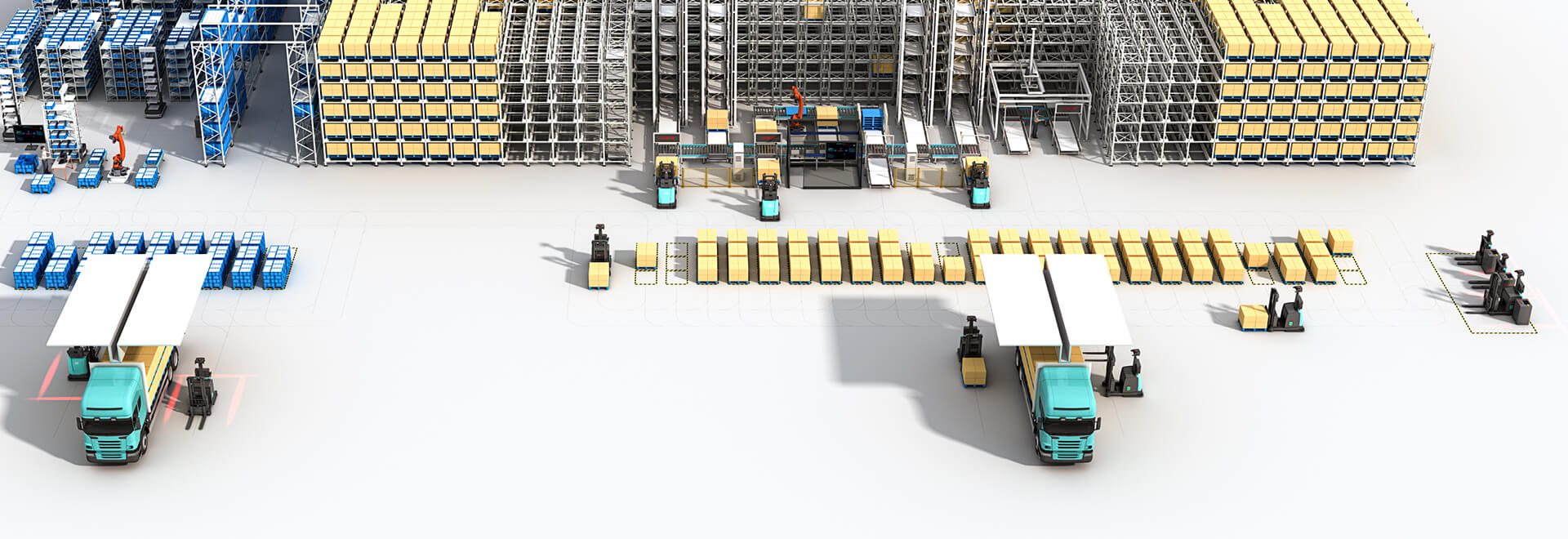

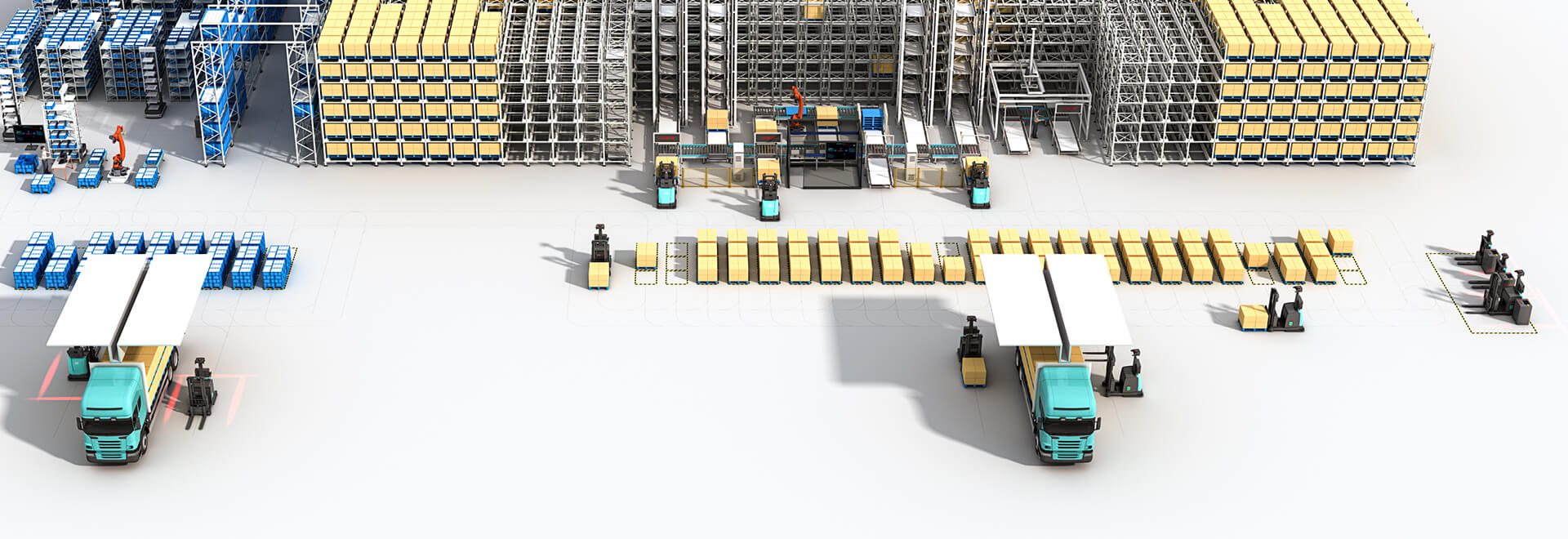

To support this transformation, many enterprises are turning to intelligent automation solutions. By deploying advanced autonomous forklifts and intelligent intralogistics systems, manufacturers aim to improve responsiveness, reduce operational costs, and enhance overall efficiency.

This project is located in Sichuan Province. The customer is a professional transformer manufacturer specializing in R&D, production, and sales, and is recognized as a leading enterprise in the electronic components sector. From manufacturing to sorting and packaging, the customer has established a refined and intelligent production management system.

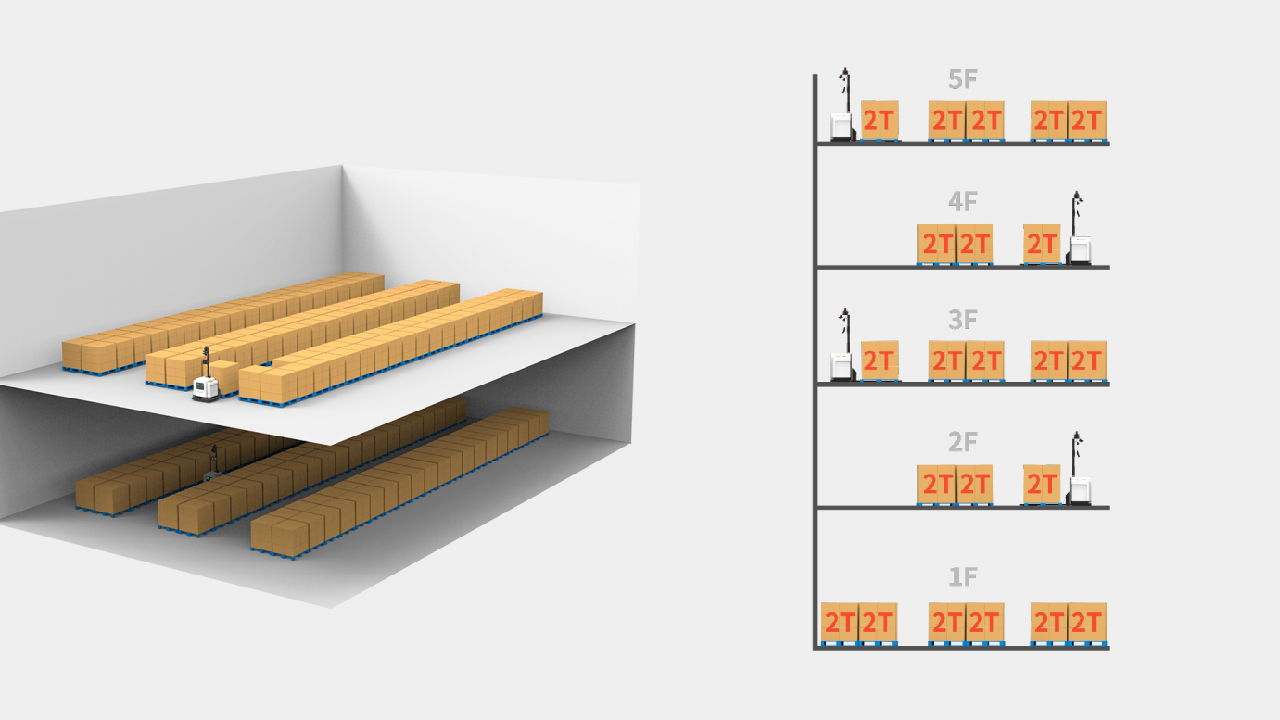

To address business growth, labor shortages, and the need for material traceability, the customer integrated its advanced manufacturing processes with Multiway Robotics’ autonomous forklift technology, enabling automated multi-floor transport of raw materials and finished products.

小身板,大能量

跨楼层搬运更轻松

适应极窄巷道运行

Compact design suitable for very narrow aisle operations

Stable performance for multi-floor material transport

High adaptability across different production and storage scenarios

The X20 serves as the primary hardware platform for the customer’s intelligent intralogistics system, supporting efficient and reliable material movement across floors.

Accurate and timely material delivery is critical for electronic component manufacturing. The WMS (Warehouse Management System) provides a comprehensive 2D visual overview of all storage locations, enabling real-time visibility into inventory distribution and status.

Key WMS functions include:

Inventory and material management

Storage location visualization

Task management and operational reporting

Statistical analysis and system monitoring

When combined with the RCS scheduling system, the solution ensures stable system operation and accurate, orderly material handling.

Multiway Robotics has extensive experience across the 3C and electronics manufacturing supply chain, from upstream component production and midstream module assembly to downstream packaging and distribution. Its flexible and scalable solutions enable rapid deployment and easy material switching based on production requirements.

Beyond electronics, Multiway Robotics’ autonomous forklifts and intelligent logistics solutions are widely applied across industries including pharmaceuticals, food & beverage, machinery manufacturing, automotive parts, chemicals, and cold chain logistics. The company has served hundreds of enterprises, including more than 40 industry leaders, delivering long-term operational value.