Case Study | Multiway Robotics’ X20 Autonomous Forklifts Enable Multi-Floor Logistics Efficiency in Home Appliance Manufacturing

Video

Video

Case Introduction

In the era of e-commerce, home appliance consumption has grown rapidly, placing higher demands on manufacturers for timely order fulfillment and efficient warehouse operations. For manufacturers, integrating automation into material handling can significantly improve throughput and meet the high-frequency inbound and outbound requirements of modern warehouses.

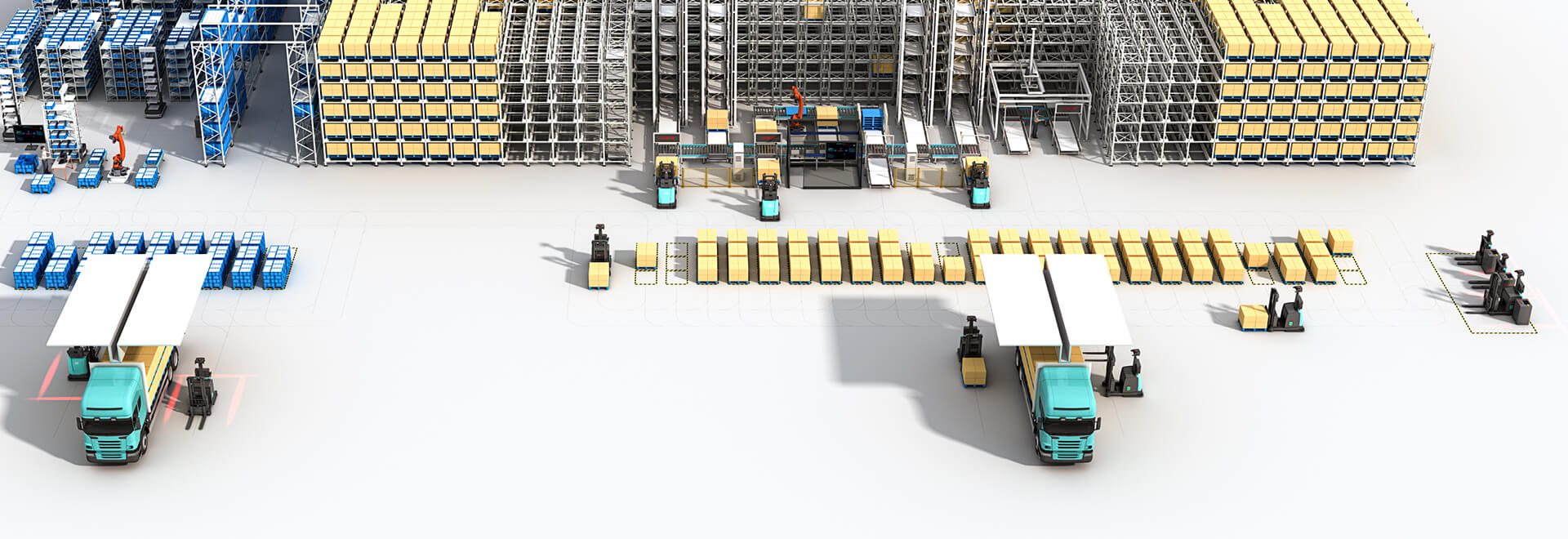

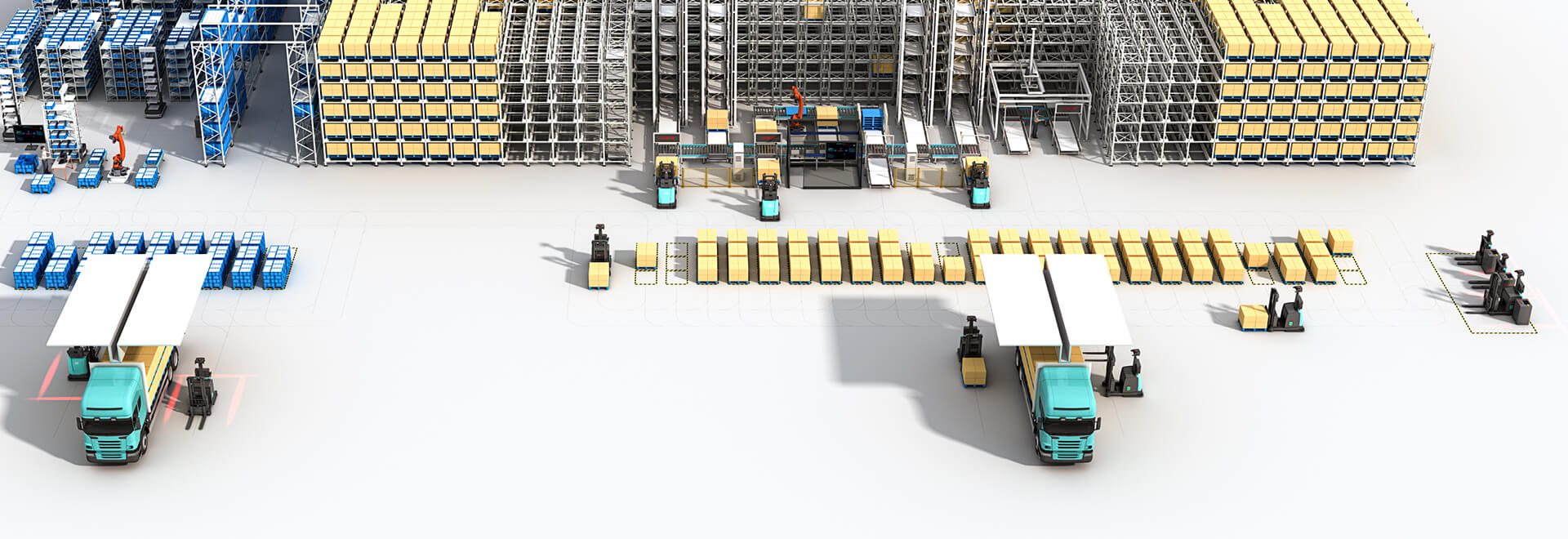

This case highlights how Multiway Robotics deployed the X20 autonomous forklifts in a multi-floor warehouse of a leading home appliance manufacturer, demonstrating the benefits of automated material handling in complex logistics scenarios.

The project site is located in Zhongshan, Guangdong Province. The warehouse handles small home appliances, which were previously transported manually across floors using elevators. Challenges included:

To address these challenges, Multiway Robotics provided a hardware-software integrated solution, including:

X20 Autonomous Pallet Forklifts

RCS (Robot Control System) for scheduling and coordination

WCS (Warehouse Control System) for equipment management and elevator integration

The system enabled efficient, high-precision material handling across multiple floors, relieving logistics pressure and supporting more refined production management.

微蜂X20

跨楼层搬运更轻松

适应极窄巷道运行

Key Features

The site involved material transfer between 1st, 4th, and 5th floors.

The WCS centrally manages all connected devices and integrates with elevators, allowing autonomous forklifts to operate continuously without manual elevator intervention, significantly increasing throughput.

X20 forklifts use advanced laser SLAM navigation to scan surroundings 360°, autonomously map the environment, and adapt to complex warehouse layouts.

No structural modifications to the warehouse were required, enabling rapid deployment and efficient inbound/outbound operations.

▲

By deploying multiple X20 forklifts for coordinated material handling: