Introduction:

The medical device industry is closely connected with multiple sectors such as machinery, pharmaceuticals, and electronics. It is a high-tech industry that integrates technology and knowledge, with products covering instruments, electronic equipment, medical materials, and various devices. As the storage hub for these products, warehouse management efficiency directly influences the overall operation of the enterprise.

Vision System Empowerment — Enabling Flexible Solution Upgrades

In recent years, with national support in both economic and policy aspects, the medical device industry has gained increasing attention and has seen rapid overall growth, creating significant development opportunities for its logistics operations. More and more automated logistics equipment is gradually replacing manual work, enabling intelligent and unmanned internal logistics, greatly improving efficiency and reducing logistics costs.Recently, Multiway Robotics partnered with a well-known medical device company in Tianjin to build an intelligent logistics system, achieving full-warehouse automation and smart upgrades. Based on the customer’s on-site requirements, Multiway adopted a small counterbalanced autonomous forklift as the core carrier, empowered by machine vision and a complete upper-level system, to construct intelligent logistics infrastructure. This provided the customer with a highly flexible and highly efficient intelligent logistics solution. The project details are as follows:

- Project Scenario: 1,000 m² warehouse with beam-type racking

- Material Handled: Full-pallet medical devices

- Handling Workflow: Incoming temporary storage area → Put-away / Picking from racks → Shipping / Picking area

Warehouse locations and inventory information cannot be effectively managed.

Manual operations are difficult to supervise, resulting in significant cargo damage.

Located in the northern region and suburban area, the work is monotonous and staffing is difficult.

Heavy reliance on manual work leads to slow picking/placing and frequent operational errors.

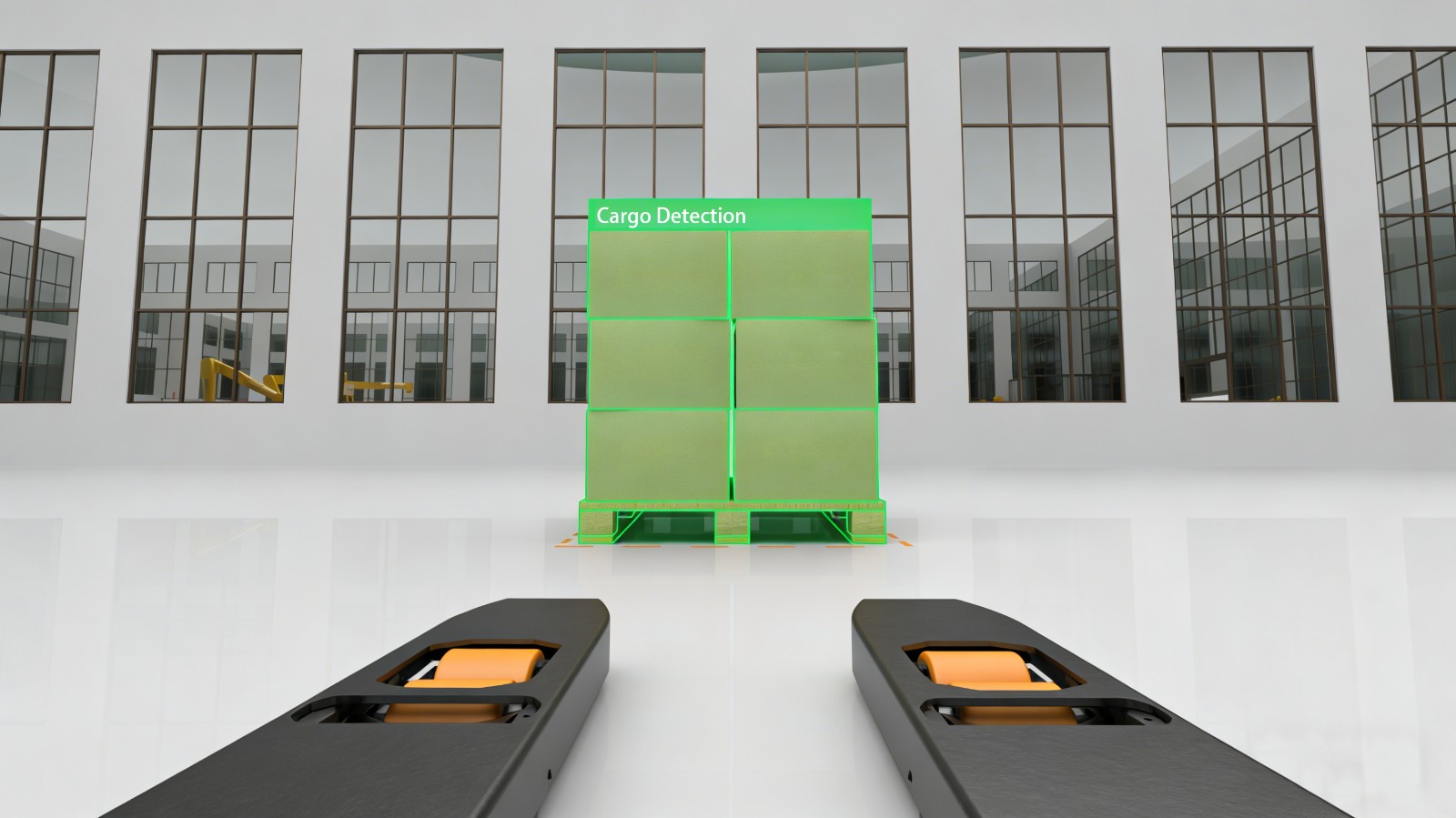

Using a small counterbalanced autonomous forklift combined with a pallet detection system to achieve unmanned and precise automatic picking and placing of goods.

△ Real shot of the lights-out intelligent warehouse

Efficient operations and information traceability to enhance management effectiveness

Intelligent and Highly Efficient Fully Automated Operations

The medical device company’s warehouse is a 1,000 m² beam-type racking facility located in a northern suburban area, where recruitment is difficult. Relying solely on manual operations resulted in slow picking and placing, as well as frequent errors. In response, Multiway Robotics selected small counterbalanced autonomous forklifts based on the customer’s on-site conditions, enabling full-warehouse automation with precise pallet handling. This greatly improved operational efficiency while addressing the labor shortage issue.Inventory / Location Information Tracking

During manual operations, warehouse location status and daily inventory information cannot be effectively controlled. By upgrading the warehouse with Multiway autonomous forklifts to achieve full automation, the entire warehouse can operate with fully paperless processes and real-time traceable information management.High-precision Docking / Reduced Cargo Damage Rate

The company’s manual operations lack effective supervision, often resulting in cargo damage. Multiway Robotics empowers autonomous forklifts with machine vision, using “intelligent pallet posture recognition” to quickly locate pallet positions and achieve precise picking and placing. It supports pallet offset of ±30 cm and ±30°. In addition, Multiway autonomous forklifts feature 360° safety obstacle avoidance, significantly reducing the cargo damage rate.△ Pallet Detection SystemLogistics automation and intelligence have become major development trends. To address complex scenarios across different industries, Multiway Robotics uses autonomous forklifts and AMRs as core carriers, implementing strict standards from product selection and solution design to project execution. The goal is to provide customers with highly efficient, highly flexible, and highly scalable intelligent intralogistics solutions.