Case Introduction

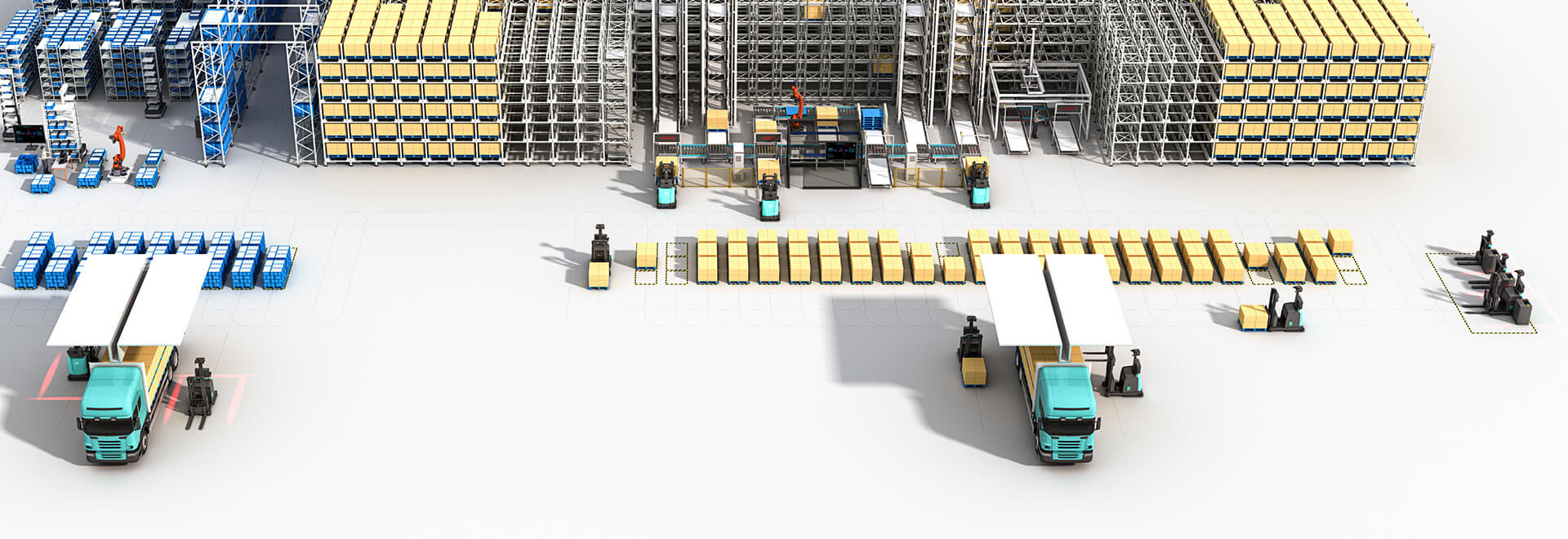

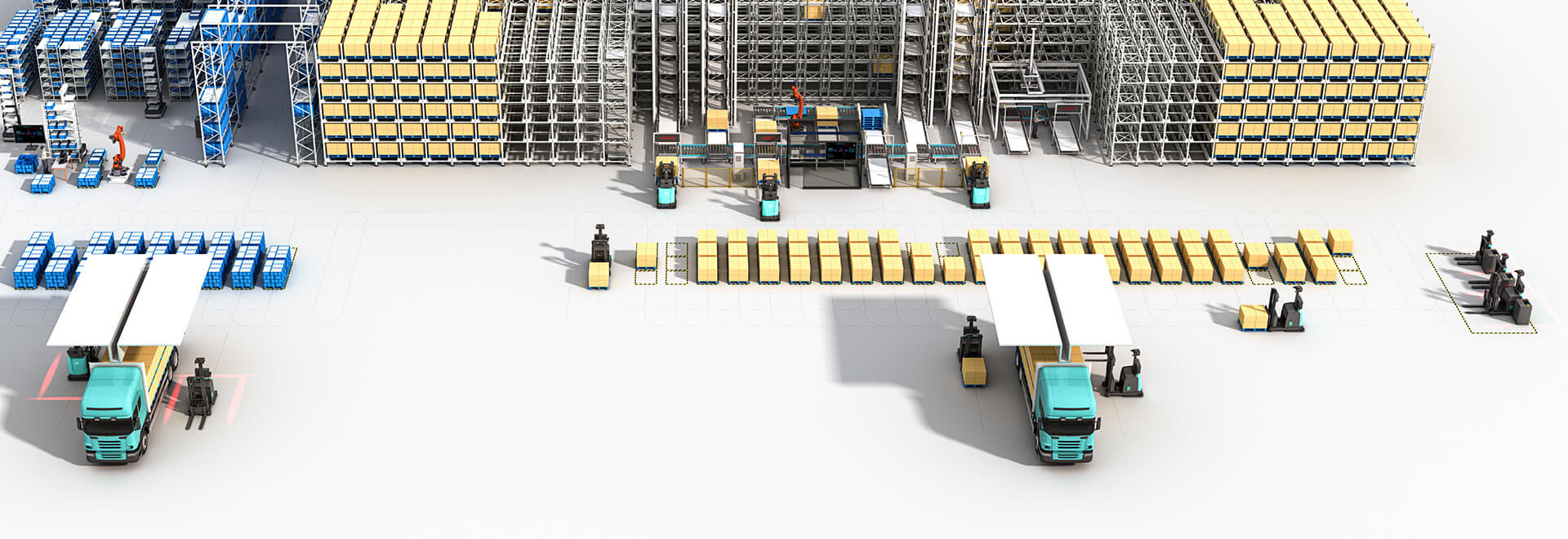

In an era of rapid development of digitalization and intelligence, companies are seeking transformation and upgrading to improve their competitiveness and efficiency. With its leading unmanned forklifts and intelligent logistics solutions, Multiway Robotics has joined hands with Sumitomo, a Fortune 500 company, to successfully achieve the automation upgrade of production line logistics.

MW

Sumitomo aims to achieve automatic loading and unloading of barrels and empty pallets on the production line on the first floor of the workshop by introducing a robot system of unmanned forklifts + robotic arms. This measure is not only to improve production efficiency, but also to reduce labor costs, reduce errors and risks caused by manual operations, and at the same time improve the intelligence level of the overall logistics process to create a more efficient, accurate and safe production environment.

MW

According to the project requirements, Mowei Robotics has developed a detailed and comprehensive plan, which covers many aspects, including special environmental requirements, regional layout and route planning, handling process and equipment quantity, and regional planning instructions. At the same time, the project equipment selection, system description, acceptance standards, and quality warranty services are clearly defined and carefully arranged to ensure that every link in the project implementation process is well-regulated and orderly.

MW

In terms of equipment selection, the project uses the MW-R20 forward-reaching unmanned forklift as the main handling equipment. This model has excellent performance parameters, and its load capacity meets the handling requirements of tanks of different specifications, and can accurately and efficiently complete various handling tasks. At the same time, the project is also equipped with a complete system, including the warehouse management system WMS, the scheduling management system RCS, the equipment management system WCS and the Horizons vision system. These systems work together to achieve full-chain intelligent management from task allocation, equipment scheduling, inventory management to cargo identification and monitoring, greatly improving the efficiency and accuracy of logistics operations.

MW

Process 1: Manual delivery process

Before manually releasing the goods, use PDA to apply for task issuance.

Process 2: Elevator conveyor line → Area E

The empty cans/empty pallets coming out of the elevator flow to the end of the conveyor line, where they are automatically identified by Sky Eye (after they are fully in place), and different handling tasks are triggered after different carrier types are distinguished.

Process 3: Area E → Filling area/Conveyor line

A person uses a PDA to issue a task to call for empty cans and specifies that the robot arrive at filling room No. 1 or No. 2. After the robot picks up the empty can and arrives at the designated point, the robotic arm removes the lid of the empty can.

Process 4: Filling room → Area F

After the filling of materials in the filling room is completed, the material information is manually scanned and entered using a PDA and the tank number is bound. The full tank handling task is issued and the filling room position 1/2 is specified; or the MES system issues the material information and the full tank offline handling task.

Process 5: Sampling location C → elevator conveyor line

After the flipping mechanism shakes the powder evenly, the can is removed manually and sampled. After the sampling is completed, the release button is pressed manually and the robot moves the can to the conveyor line at the elevator entrance.

Process 6: Empty pallet: Empty pallet storage location W → Empty pallet conveyor line

When an empty pallet is needed, a human uses a PDA to issue an empty pallet request task, and the robot removes the top empty pallet from the empty pallet storage location and places it on the platform of the conveyor line next to it.

By introducing unmanned forklifts and their intelligent logistics solutions, the Sumitomo project has achieved efficient transportation of tanks and barrels between different areas. The unmanned forklifts can accurately complete a series of operations such as picking up, transporting, and releasing goods according to the preset procedures and paths, greatly shortening the handling time and increasing the speed of material flow, making the production line run more smoothly and significantly improving the overall production efficiency.

In the traditional logistics model, handling work often requires a lot of manpower, and manual operation has certain limitations, such as work efficiency is easily affected by factors such as fatigue, and operation accuracy is difficult to ensure. After the introduction of robot automated handling, the handling tasks that originally required multiple people to complete can now be performed efficiently and stably by robots, reducing dependence on manpower, reducing labor costs, and avoiding potential risks caused by manual operation errors.

The special environment of the project site, such as dust on the ground, may have an adverse effect on the health of personnel and the operation of equipment. The solution of Mowei Robotics fully considers these factors and proposes corresponding rectification and protection measures. At the same time, during the automated operation process, the robot can effectively reduce the contact between personnel and potential sources of danger, reduce the probability of safety accidents, and create a safer working environment for employees.

The introduction of robots and automation systems does not simply replace manpower, but realizes the collaborative operation of people and machines by optimizing work processes and integrating resources. In this model, employees can be liberated from heavy and repetitive physical labor and participate more in higher-value work such as equipment monitoring, maintenance management and process optimization, which improves employee job satisfaction and career development space, and also creates a more diversified and efficient talent team for the company.

Sumitomo's realization of automated production line logistics upgrades is a key step in its intelligent transformation. The success of this project not only brought significant economic benefits and work efficiency improvements to Sumitomo, but also provided the industry with valuable practical experience and reference examples.