Case Introduction

This case focuses on a globally renowned food production company. As a leader in the food industry, the company took the initiative to introduce robot solution to address production challenges. Among the numerous robot equipment providers in the market, they adhered to a technology-first principle and chose Multiway Robotics.

Due to the company's vast quantity of small and irregularly shaped items with diverse storage requirements, manual handling efficiency was low, leading to high error rates. This made it difficult to meet business development needs. Moreover, under the influence of the new retail model, the demand for goods production continuously increased. The inflow and outflow of goods were substantial, requiring high efficiency and accuracy. As a result, there was an urgent need to intelligently optimize the handling process to cope with the complex production environment and meet the requirements of high security and accuracy in operation.

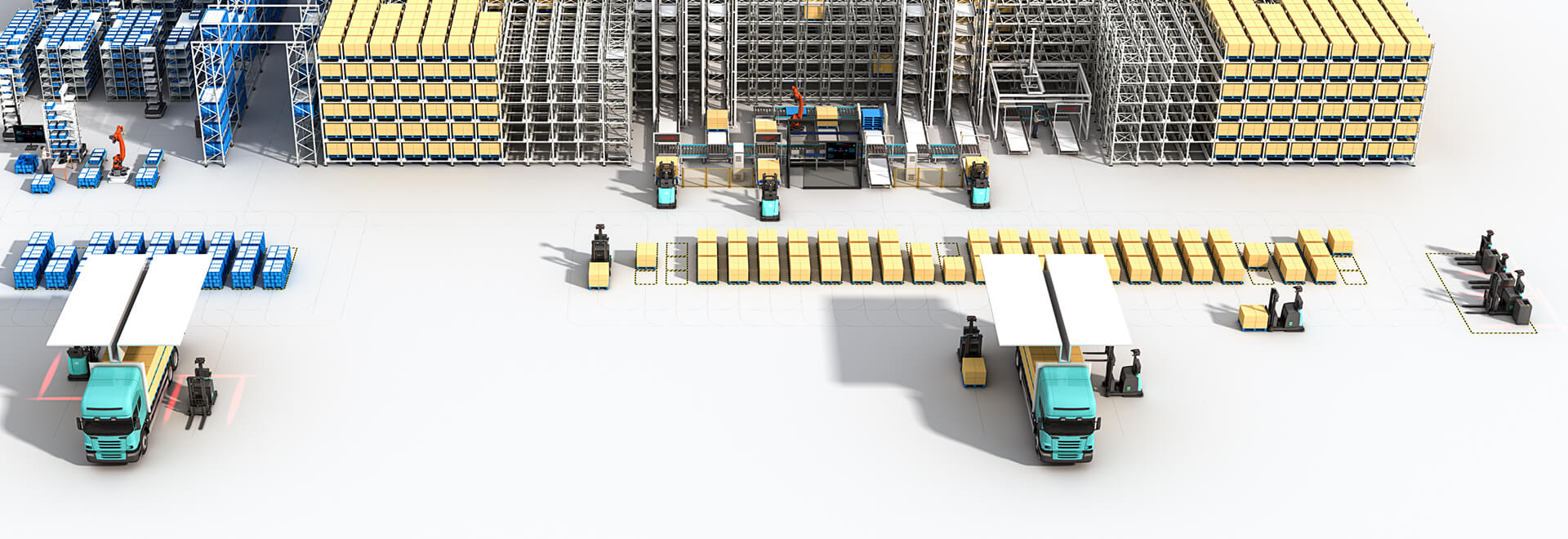

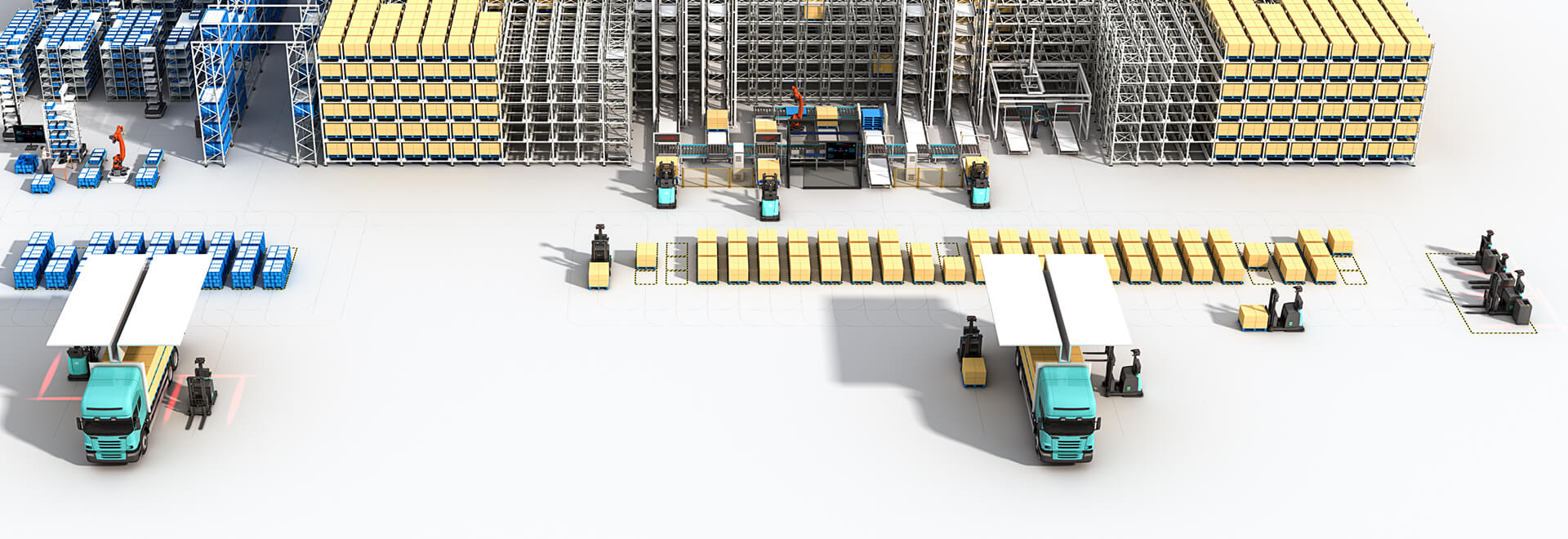

Seamless Integration From Production Line to Automated Warehouse

The flexible and intelligent logistics solution combines hardware products Counterbalanced Stacker + software WMS/WCS/RCS/SkyEye systems , meeting the needs of material handling, efficient storage, and access in both inbound and outbound processes, as well as within the production line area.

On-site, there are a total of 19 material picking points and 16 unloading points, including 12 lift positions and 3 automatic conveyor lines. The AGVs interact with the system through the WMS system, enabling remote communication with IO modules such as lift platforms and production lines. This allows for rapid response to task requirements and flexible handling.

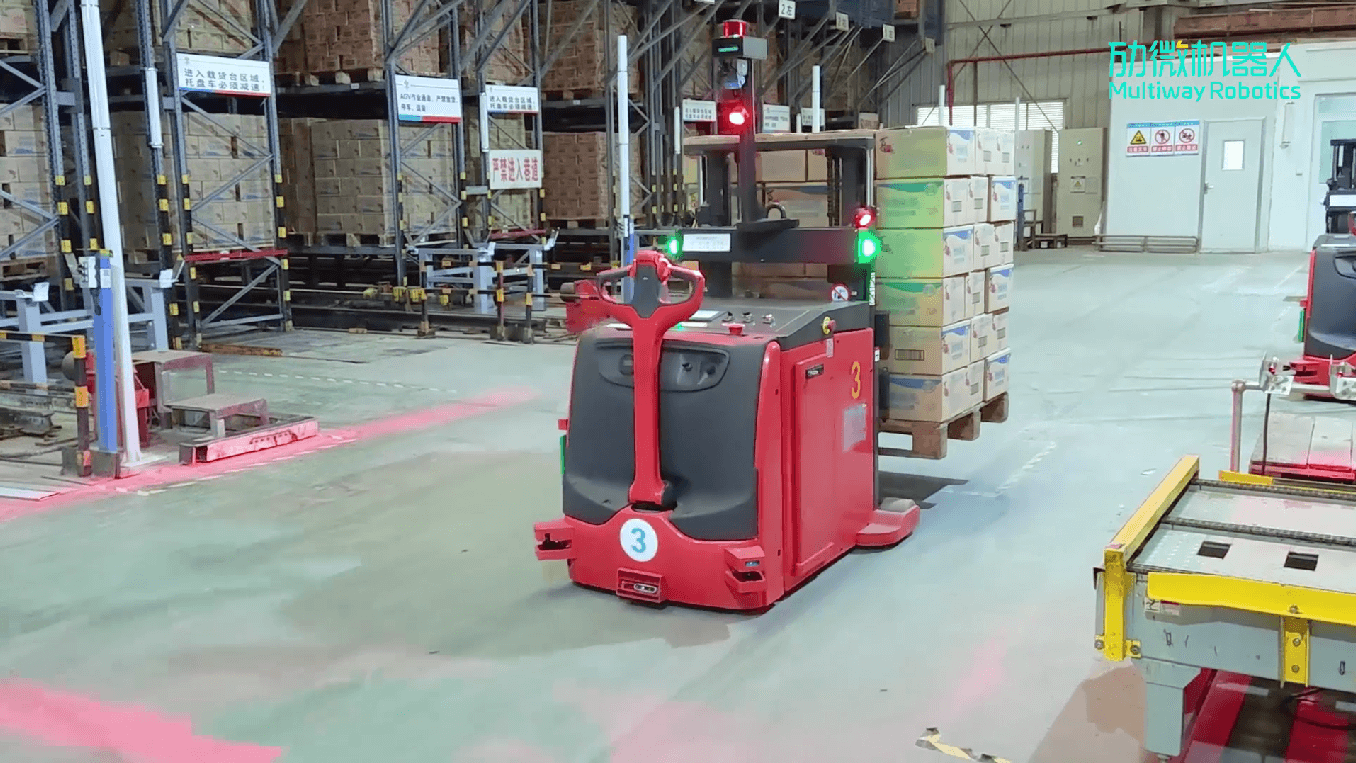

Cluster Scheduling for Efficient Collaboration

Once the conveyed goods are in place, unmanned forklifts automatically arrange unloading stations based on the storage status. Multiple unmanned forklifts operate autonomously throughout the entire process in areas including the goods placement zone, loading points, unloading points, stacking conveyor lines, and automatic charging zones.

The system supports optimal path planning, intelligent task scheduling, and intelligent traffic control scheduling. By integrating with on-site ERP/WMS/MES systems, data barriers are broken down. This allows real-time updates of storage information at loading and unloading points. The unmanned forklifts operate at high speeds, swiftly completing all handling tasks, resulting in an overall handling efficiency increase of over 20%.

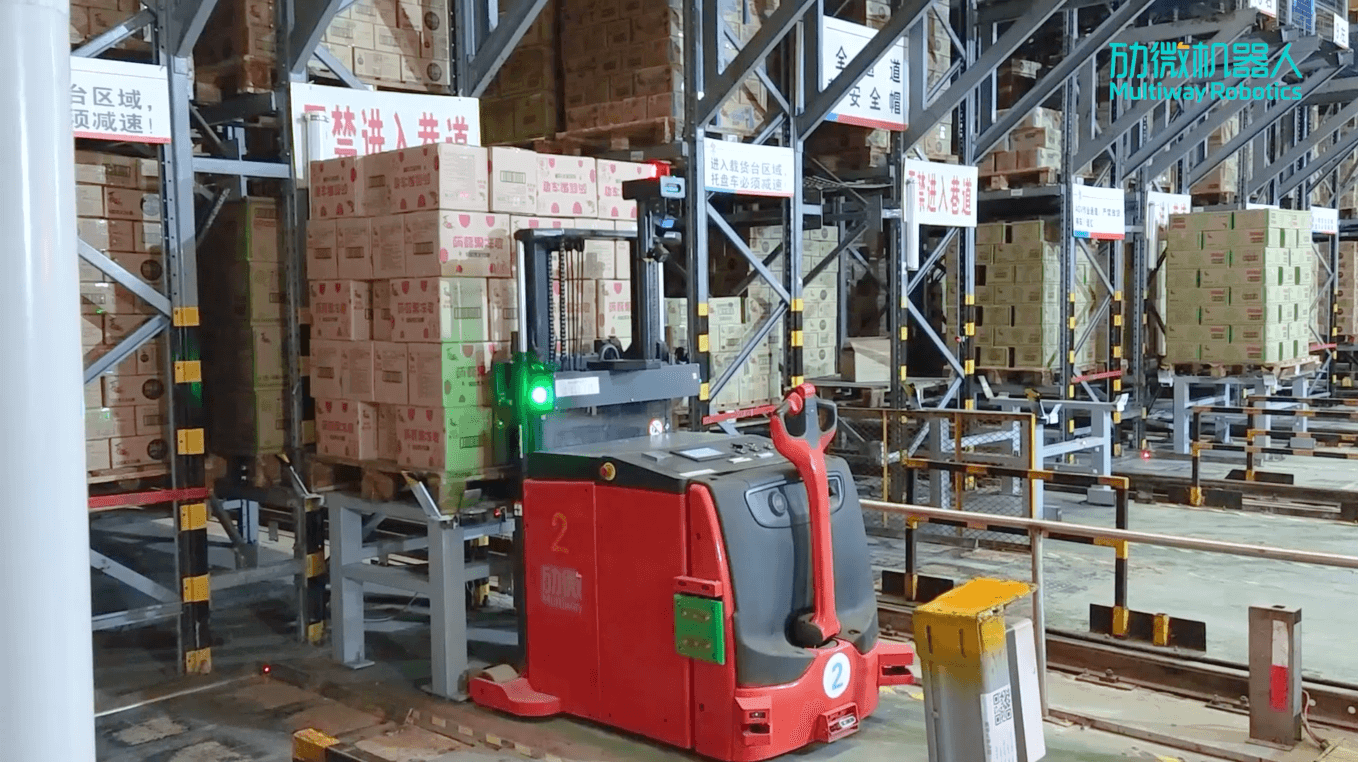

Adapting to Complex Environments Dynamically

In response to the factory's intricate operational setting, including challenging narrow passages, densely stacked storage areas, and haphazardly placed pallets at loading points, the unmanned forklifts employ an advanced combination of laser navigation and SkyEye system's visual approach. This method, as compared to using a single navigation approach, better suits both unmanned and human-robot hybrid scenarios.

It can dynamically adapt to various application scenarios within the factory, such as internal transportation and production line transfers. It achieves sub-millimeter level positioning accuracy during operations, dynamically adjusting to the surrounding environment. This ensures precise and efficient movement between storage warehouses and production lines.

Advantages of Multiway Solution

Swift Deployment for Rapid Implementation

Compared to other solutions that entail downtime and production halts, Multiway Robotics' intelligent logistics solution features modular product deployment and platform system delivery capabilities. Our solution not only supports scenarios where humans and vehicles coexist and collaborate but also caters to fully unmanned setups like lights-out factories and warehouses.

In the current project, there's no need for environment remodeling. The deployment can be swiftly executed, reducing initial project investments. Additionally, for subsequent product upgrades and process optimizations, adjustments to operational paths or equipment quantities are all that's required. This flexibility and convenience lead to smaller secondary investments.

Flexible Response to High Production Demands

To address the demands of heavy production tasks, Multiway Robotics offers a variety of solutions. By employing a parallel strategy of automatic and manual charging, the company ensures 7*24 hour continuous robot operation without the need for production stoppages.

Robot equipment can be flexibly adjusted according to handling requirements, enabling dynamic adjustments of handling capacity. The software system adapts to varying cargo volumes by configuring different inbound and outbound strategies, thereby meeting the year-round business requirements.

Strong Stability and High Safety

Every product from Multiway Robotics undergoes rigorous quality inspections and must pass high-standard MTBF (Mean Time Between Failures) testing to ensure operational safety and stability. Furthermore, a multi-faceted protection approach is employed, including safety sensors, algorithm-controlled system safeguards, and visual system-assisted protection. These measures enhance vehicle safety and fulfill the requirements for safety protection in complex working conditions.

Unmanned forklifts utilize dynamic adaptation to the environment through laser navigation. Equipped with standard visual cameras, they achieve stereoscopic obstacle avoidance. Additionally, front and rear collision bars and emergency stop buttons are integrated, ensuring 360-degree safety for people, vehicles, and cargo.