Four-Way High-Density Storage Expansion! Multiway Robotics Empowers “Chemical Enterprise” to Upgrade Smart Warehousing and Logistics

Video

Video

Case Introduction

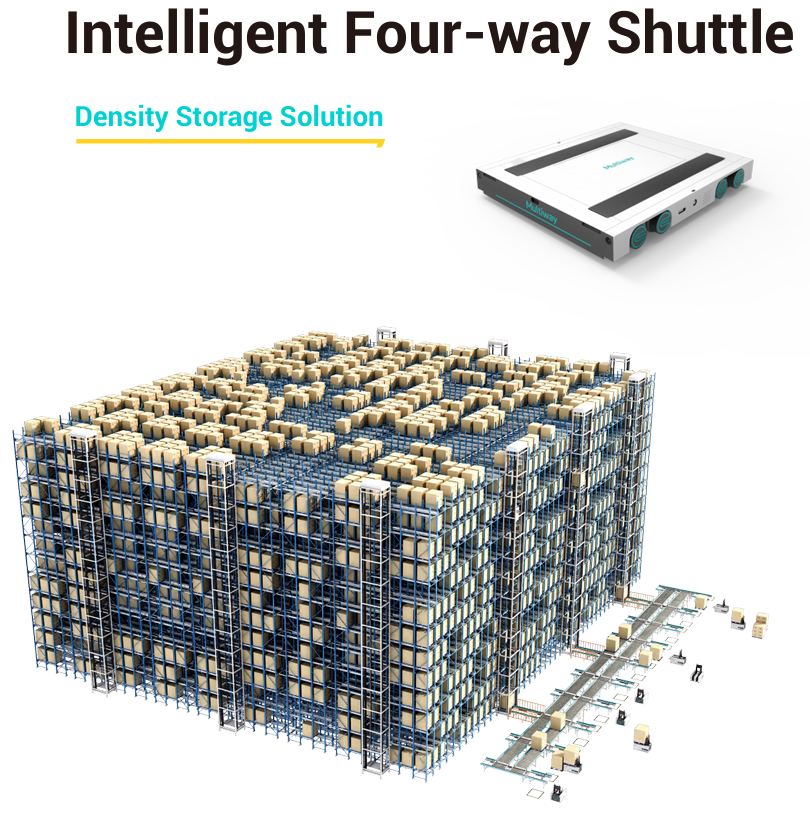

Driven by the demand for lean and intelligent logistics management, the enterprise is gradually shifting from a traditional warehouse operation model to an intelligent warehousing model. The advanced smart four-way high-density storage system solution will effectively alleviate rising labor and warehousing costs, achieving high density, high efficiency, and transparent inventory information in logistics storage.

This case focuses on a chemical products manufacturing enterprise that specializes in the development and application of functional materials such as high-end adhesives and sealants. The company is a well-recognized industry leader.

By introducing Multiway Robotics' intelligent four-way high-density storage system solution, with the “intelligent four-way shuttle” as the core hardware, combined with the self-developed Warehouse Management System (WMS), Resource Control System (RCS), and Warehouse Control System (WCS), the enterprise achieves intelligent and digitalized warehousing operations, reduces labor costs, and improves operational efficiency.

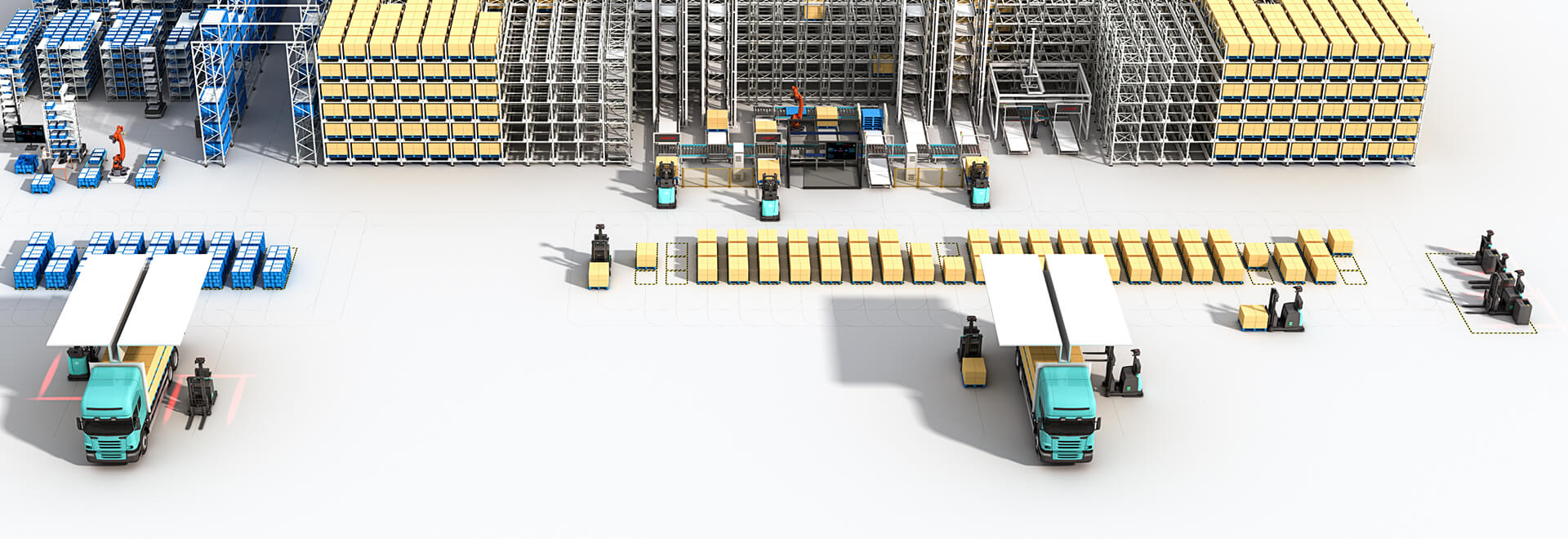

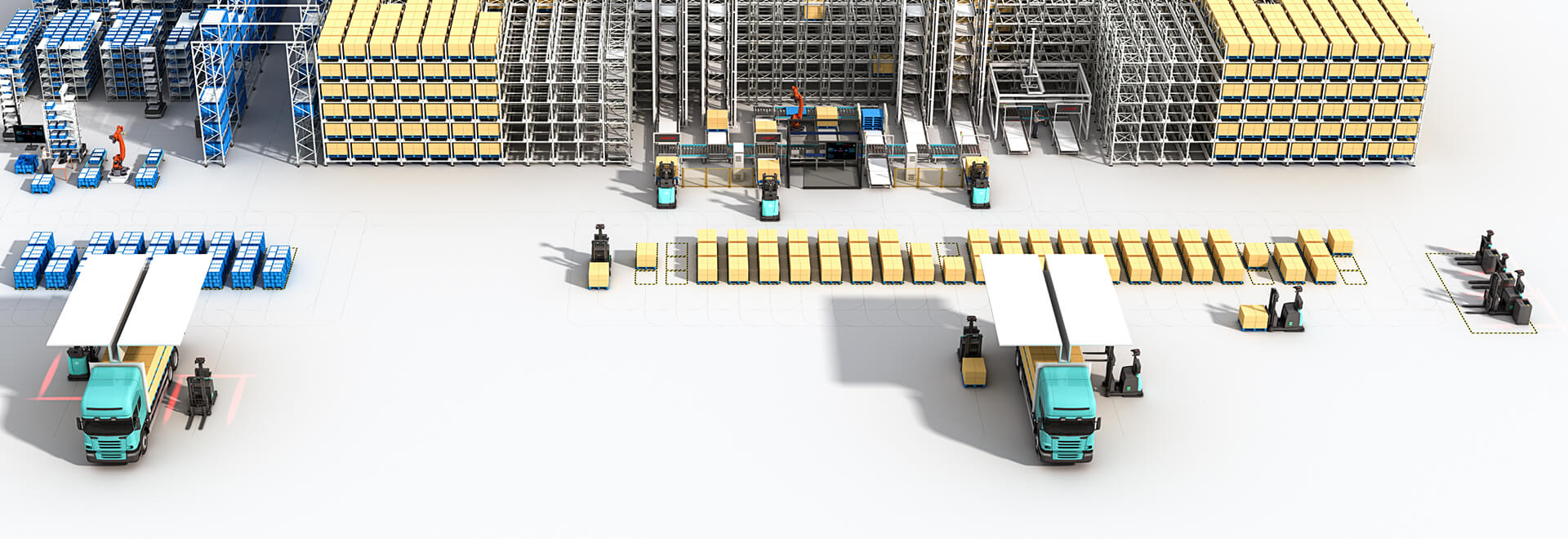

Four-Way High-Density Storage System Solution

Multiway Robotics provides the project with a complete set of process equipment, covering the entire workflow from inbound receiving to outbound sorting. The solution offers significant advantages in terms of system comprehensiveness, equipment advancement, and economic efficiency.

During inbound operations, unit pallets that have passed incoming quality inspection are placed on the inbound station by forklifts. After being scanned and bound via PDA, the goods are transported through the conveyor line, pass through the inspection area, and are lifted to the designated level. The four-way shuttle will deliver the goods to the optimal storage location based on the WMS slot allocation, achieving high-density storage. Outbound operations follow the reverse process, adhering to the first-in, first-out (FIFO) principle.

Intelligent Scheduling, Flexible Shuttling, High-Density Storage

The storage method uses a four-way high-density system, with three levels and nearly 1,000 storage locations, making full use of vertical space. Within the same building area, it achieves 3–5 times the storage capacity of traditional beam-type racks, maximizing the quantity of goods per unit of space. The conveyor system supports an inbound/outbound rate of 20 pallets per hour, operates 24 hours a day, and handles an average daily transport volume of up to 57.6 tons.

▲Goods pass through the conveyor line and go through the inspection area for weighing and dimension measurement.

Warehouse Control System (WCS)

Integrating All On-Site Equipment Flows

Through the Warehouse Control System (WCS), Multiway Robotics enables efficient interaction with the dimension inspection machine, weighing module, chain conveyor, lift, and KBK-assisted sorting equipment, integrating all on-site equipment flows for unified management. This achieves full-process automation of raw material inbound, outbound, and sorting operations.

▲The intelligent four-way shuttle transports goods and changes levels via the lift.

Warehouse Management System (WMS)

Achieving Transparent Inventory Data and Information

In addition, the Warehouse Management System (WMS) enables inventory data management, operation management, slot management, equipment health monitoring, and intelligent reporting, creating a transparent and convenient warehouse management system.

Significant Improvement in Operational Efficiency

Intelligent and Lean Production

In traditional storage modes, space limitations often lead to stacking materials, resulting in last-in, first-out handling that can cause material backlog, damage, or expiration waste. In the intelligent four-way high-density storage warehouse, goods follow the first-in, first-out (FIFO) principle, improving storage quality and preventing natural aging or loss of materials.

▲Goods outbound follow the first-in, first-out (FIFO) principle.

Replacing the traditional storage mode with the intelligent four-way high-density storage system not only reduces costs and improves efficiency in warehousing, but also integrates the logistics system into the entire production process, forming an efficient closed loop. Through effective connections between the production line, automated storage, and sorting line, the overall production flow is optimized, enhancing enterprise performance.

The successful implementation of the intelligent four-way automated storage project serves as a strong testament to Multiway Robotics’ expansion into the storage and retrieval domain. To date, Multiway Robotics’ hardware portfolio includes a full range of unmanned forklifts, AMRs, unmanned tow vehicles, and four-way shuttles. On the software side, the digital Multiway Cloud system, combined with the Warehouse Management System (WMS), Warehouse Control System (WCS), Resource Control System (RCS), and the flexible visual solution “SkyEye,” establishes a unified smart logistics infrastructure, comprehensively empowering customers in upgrading to intelligent logistics.