Case Introduction

In the automotive industry, there is a wide variety of specifications for vehicle components, and the operational environment is complex with high safety standards. This presents numerous challenges for various aspects such as on-site management, warehouse planning, and equipment coordination on the production and manufacturing side.

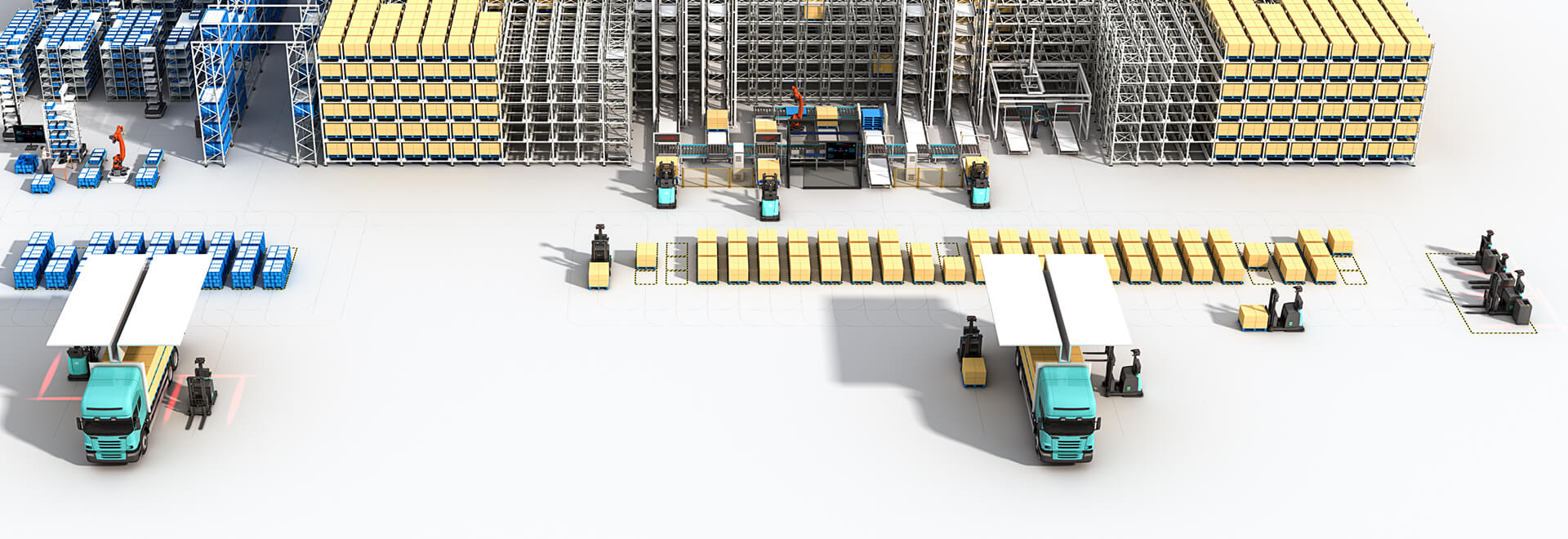

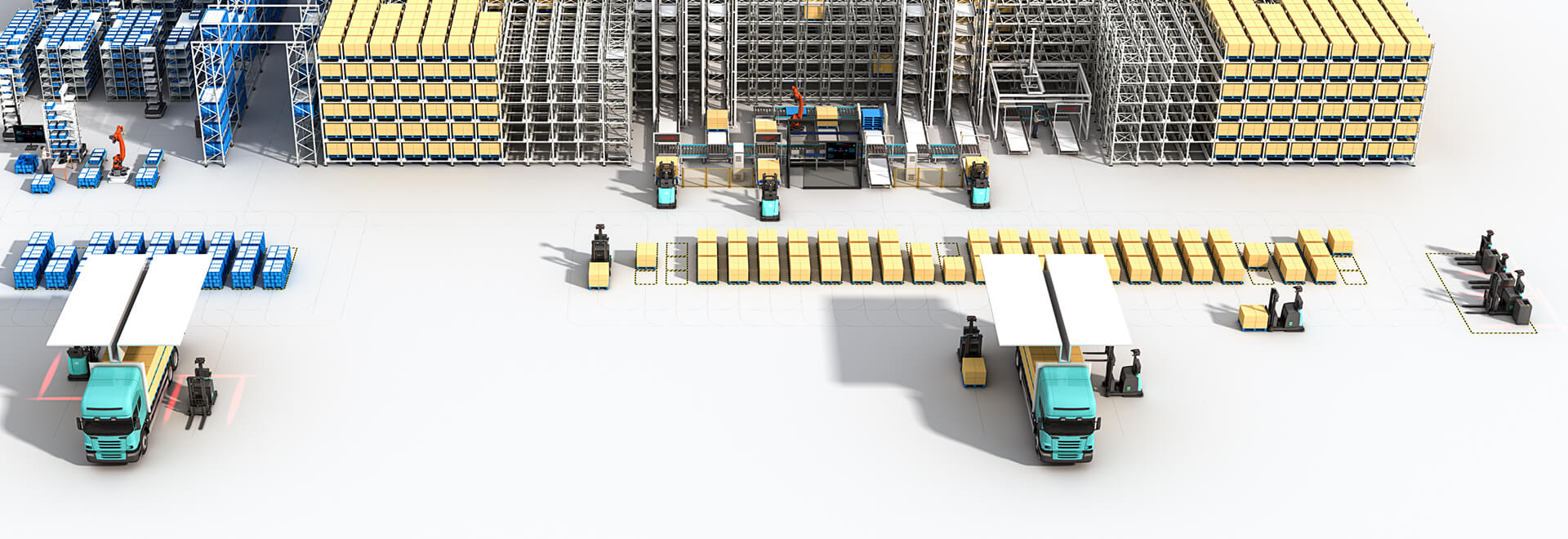

Multiway Robotics assisted an automotive component production group in achieving intelligent logistics upgrades across various scenarios, including from the production line to the loading platform.

The main challenges faced by the automotive component production factory are as follows:

High Cost Investment: 24-hour non-stop operations lead to high labor costs.

High Labor Intensity: High stacking requirements (6 layers stacking) result in significant manual labor.

Difficult Inventory Management: Inability to synchronize material information updates, leading to difficult inventory management

As per the customer's requirements, there is a need to achieve automated inbound and outbound processes for finished products. This involves several different areas for material handling: production line, storage area, shipping area, and loading area.

On the hardware side, the company ultimately adopted our counterbalanced stacker MW-SE20, with a load capacity of 2000kg. This product efficiently meets the high-precision stacking requirements, high lifting, and heavy load demands of the automotive component production factory.

On the software front, Multiway Robotics utilizes self-developed robot control system (RCS), equipment control system (WCS), and warehouse management system (WMS). These systems facilitate equipment interconnection, data exchange, visualized inventory positioning, and comprehensive monitoring of vehicle operational status. Multiway also supports collaborative scheduling for multiple vehicles, mixed warehouse management strategies, and integration of various device system modules, achieving intelligence within the facility and optimizes storage management.

Leveraging its technological advantages, Multiway Robotics adopted a technology-driven approach from product definition to development, establishing a leading integrated intelligent logistics delivery platform. This platform successfully encompasses a full range of warehouse robotics products, including unmanned forklifts, AMRs (Autonomous Mobile Robots), and four-way shuttle. Self-developed WCS, WMS, and other software systems work seamlessly together, offering a comprehensive on-site intelligent logistics solution. Through this solution, the automotive component production factory not only significantly reduces labor costs but also meets the demands of high-efficiency production cycles, effectively enhancing material handling efficiency.