Case Introduction

The logistics industry is a vast and complex system. In addition to the express delivery services directly related to ordinary consumers, the transportation of goods involved in factory areas, industrial parks, and production sites, as well as processes like production line integration, are all undergoing automation-driven transformations. Unmanned equipment is being implemented across various stages. The application of industrial robots and automation technology will significantly enhance enterprise productivity. This represents a significant aspect of smart manufacturing and is a prevailing trend in the future of industrial production.

In the logistics industry, third-party warehousing differs from regular leased warehouses. It can provide specialized, efficient, cost-effective, and accurate distribution services. Third-party logistics warehousing is characterized by high-level warehouse design that adheres to high standards for specific goods and specialized handling requirements. Compared to traditional warehousing companies, they can offer a comprehensive set of logistics services to cargo owners, including storage, loading and unloading, consolidation, order categorization, inventory management, in-transit mixing, inventory control, transportation arrangement, information management, and other requirements from cargo owners.

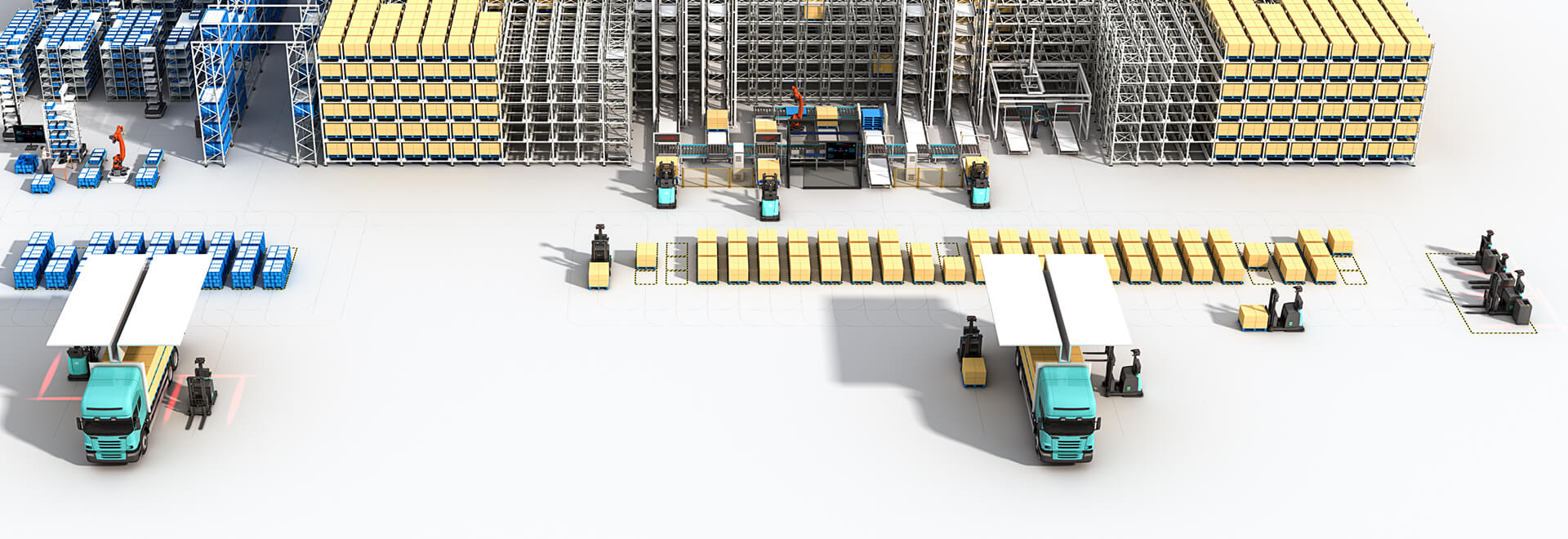

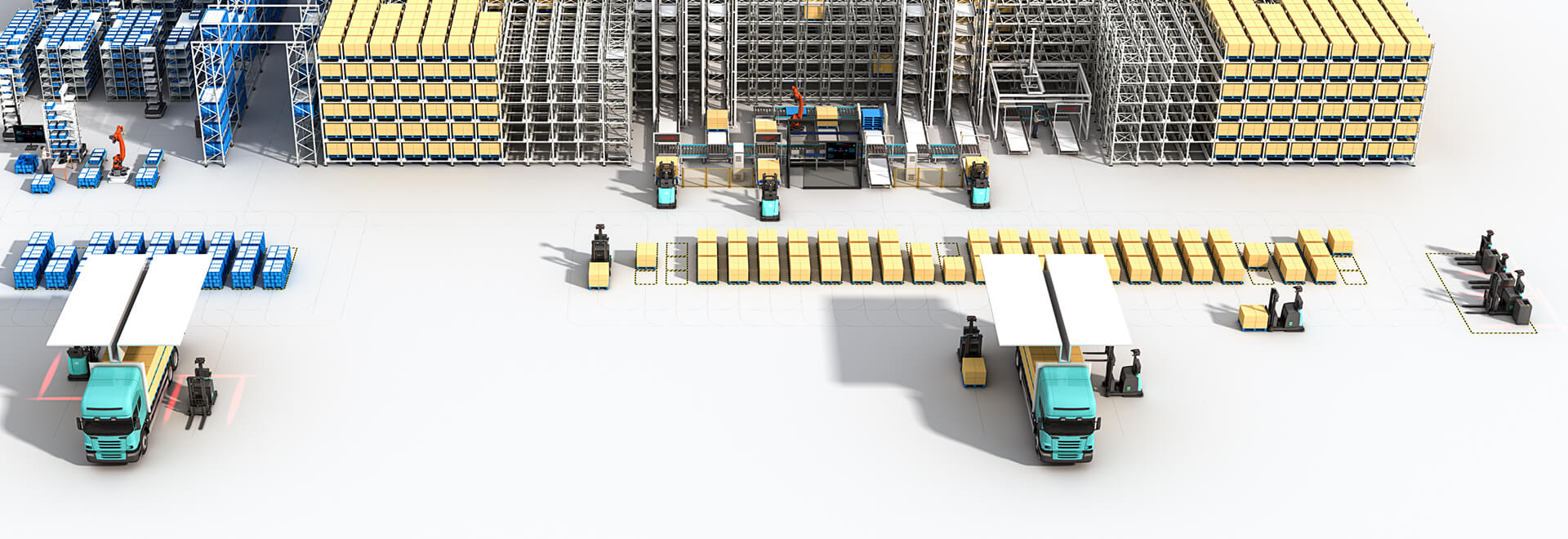

Recently, Multiway Robotics successfully achieved a full warehouse automation upgrade for this third-party logistics warehouse, realizing efficient, intelligent, and fully automated storage and logistics management. The project background is as follows:

Project Scenario: Warehouse area of nearly 10,000m², involving inbound and outbound operations, as well as picking tasks.

Material Handling: Handling of full pallets of goods.

Handling Processes: Involves common warehouse handling modes such as inbound, sorting, outbound, and inspection.

Main Challenges:

Large warehouse area of 160m (L) x 70m (W), leading to significant non-value-added operation distances.

Involvement of diverse handling processes, leading to high manual handling workload.

With increasing business volume, the costs associated with warehouse logistics are continuously rising.

Dedicated to achieving fully automated storage and logistics management for enhanced efficiency and intelligence.

Project Implementation Phases:

Phase 1 involved deploying multiple pallet trucks to handle ground-level storage tasks.

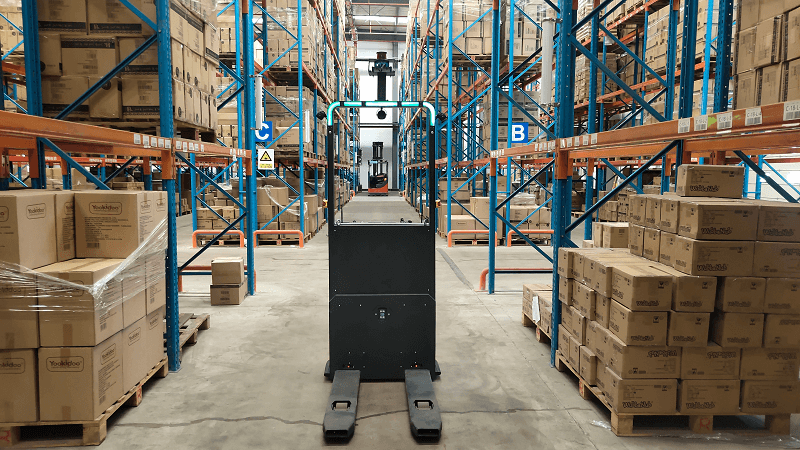

Phase 2 focused on retrofitting multiple reach trucks, specifically the MW- R14 model, for high-level rack operations (8 meters high, with 2.85-meter aisles).

Meeting Customer Needs comprehensively

1. Efficient Operations to Meet 24-Hour Demands

The third-party logistics warehouse, covering an area of nearly 10,000m², has extensive non-value-added operation distances. While a significant amount of manual work could meet the demands, it increased issues such as human resource management, coordination, and costs. To further enhance efficiency and reduce costs, Multiway Robotics tailored a specialized intelligent logistics solution for this project.

Considering the large warehouse area and other requests, Multiway Robotics customized pallet trucks for the customer. These forklifts achieve efficient automated inbound and outbound handling, addressing the challenges of low efficiency.

2. Collaborative Integration for Efficient Intelligent Automation

The warehouse encompasses a wide variety of products and involves diverse handling processes, leading to a substantial manual handling workload. Improving warehouse efficiency is key. Multiway Robotics intelligent logistics solution covers point-to-point, point-to-station, station-to-station, station-to-point, temporary station planning, fruit picking and sorting, inspections, and other conventional warehouse handling processes, thereby enhancing overall automation levels.

3. Flexible Upgrades for Cost Reduction and Efficiency Enhancement

With increasing business volume, the heavy manual workload and the need for precise storage placement further contribute to manual labor requirements, escalating warehouse logistics costs. To address this, pallet orientation visual recognition is applied to enable accurate automatic pallet placement, thereby enhancing spatial flexibility and fault tolerance. Customized protocol development ensures compatibility with various customer scenarios, saving labor costs and achieving internal logistics intelligence and flexible upgrades.

Unmanned forklifts play a pivotal role in constructing intelligent logistics systems, supporting the circulation and transfer of materials in dense storage, warehouse distribution, and intelligent manufacturing. Multiway Robotics utilizes unmanned forklifts/AMRs as the hardware foundation and empowers them with machine vision and a comprehensive upper-level system, providing clients with complete smart manufacturing and intelligent warehousing solutions. Hardware products include various types of unmanned forklifts and AMRs, while software systems include WMS, WCS, on-site management systems, and various visual solutions. Multiway remains committed to independent research and development, consistently offering cutting-edge intralogistics solutions, solving clients' fundamental issues: return on investment and user experience.