Case Introduction

With the continuous and profound development of robotics, robot applications are becoming more widespread, and the business landscape is rapidly changing. The application scenarios are becoming more specialized and complex, and the business models of end-user enterprises are increasingly diverse. Issues such as labor shortage, high labor costs, and safety hazards associated with manual labor are driving the urgent need for the replacement of heavy, repetitive, and dangerous work environments. In this regard, a 3C company has turned to Multiway Robotics to introduce flexible solution of unmanned forklifts and AMRs (Autonomous Mobile Robots), officially embarking on an intelligent logistics journey.

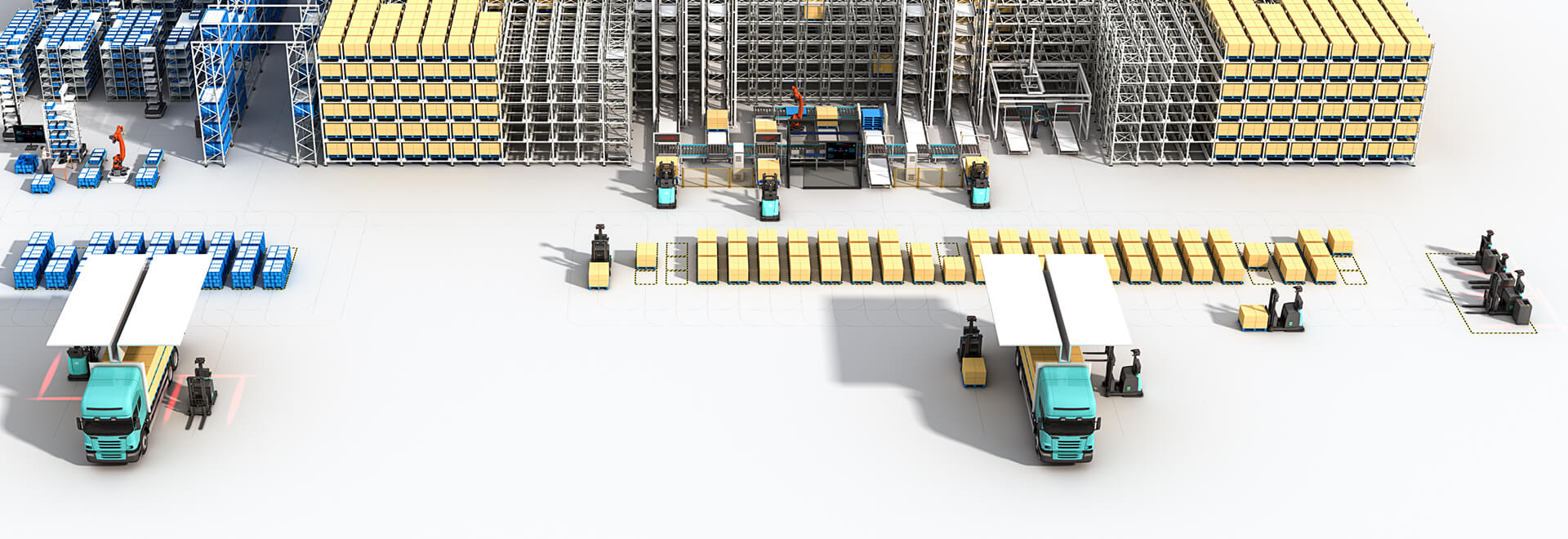

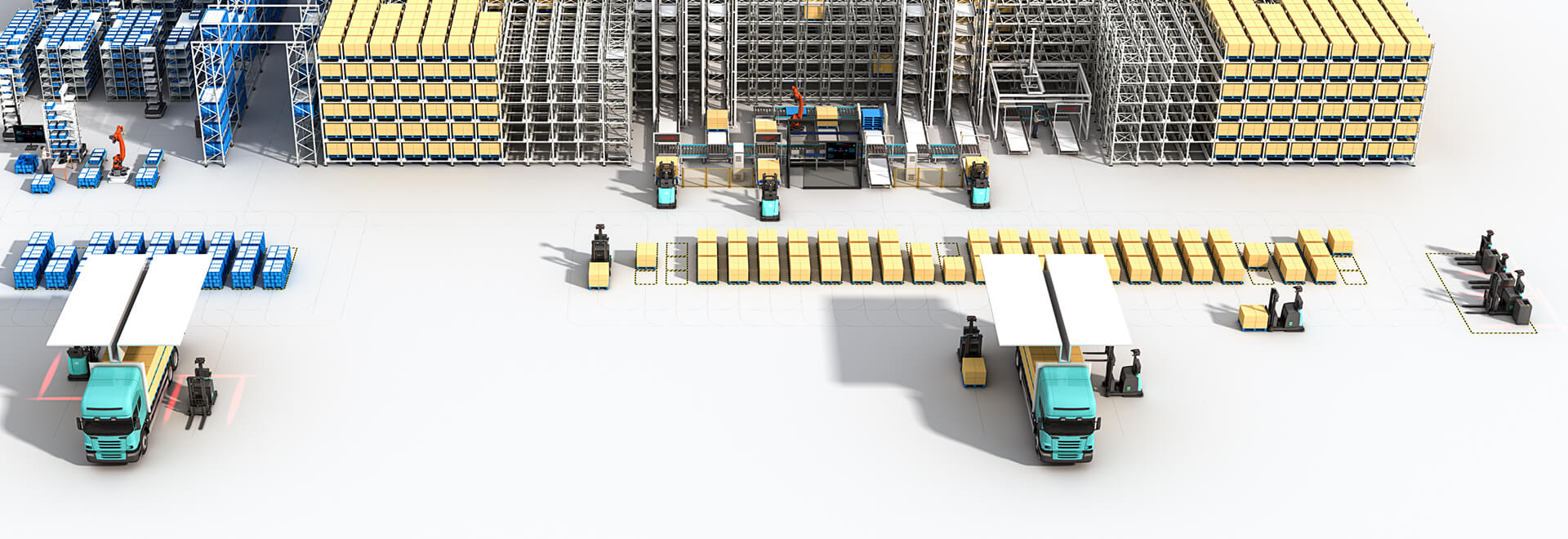

The 3C company is located in Jiangsu, China, and it not only emphasizes quality in the manufacturing process but also has strict requirements for warehousing and logistics. After gaining in-depth understanding of their business, Multiway Robotics has confirmed the solution of "Pallet Stacker MW-L14 + AMR." Empowered by the intelligent and flexible software and hardware system, this solution enables batch control of warehouse materials, achieving unmanned material handling, automated production, and inventory management throughout the factory.

Pain Points of the Project

Complex logistics routes requiring comprehensive equipment considerations.

High environmental requirements, including the need for gas protection suits and anti-static functions.

Small-sized products with a wide variety, multiple specifications, and large quantities.

Numerous manufacturing processes with different types of production equipment.

Project optimization

Project optimization

Automate the integration of production and logistics to create an efficient and smooth logistics system.

Rapidly optimize the layout of production lines to significantly improve inventory utilization.

Implement strict batch control to ensure accurate batch delivery and eliminate the risk of delivery errors.

Implement a highly flexible solution using unmanned forklifts and AMRs to meet the demands of complex on-site environments.

Multiway Robotics provides standard products and flexible solutions to meet the fragmented on-site requirements of customers. By significantly reducing the marginal costs associated with implementing intelligent logistics systems, Multiway Robotics enables batch control of materials in the 3C company's line-side warehouse, achieving unmanned material handling, automated production, and inventory management throughout the factory. This not only helps the company effectively reduce costs and improve efficiency but also demonstrates Multiway Robotics' ability to adapt to increasingly complex industry competition and meet diverse customer demands comprehensively.